Print sell by dates and more with Videojet coding and marking solutions

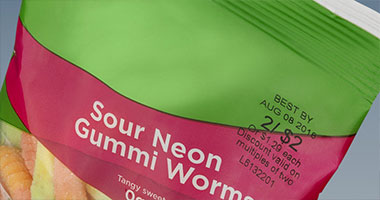

Options for printing a sell by date directly on a product or packaging include Videojet inkjet, laser, thermal transfer and thermal inkjet printers, as well as case coding labelers and printers.

A sell by date is applied on a product by a manufacturer to help retailers, end-users, and consumers determine a product’s freshness or efficacy. Numbers, letters, and even barcodes can identify a sell by date and help ensure product safety.

Considering the surface to be printed or marked (e.g. plastic bags, cardboard boxes, cables, heat shrinkable sleeves, pouches, kraft paper bags, PET bottles, metal or almost any other packaging material or product), Videojet can help select the ideal solution to print a “best by” date, “manufactured on” date or “sell by” date.

Videojet solutions for printing human and machine-readable lot numbers include continuous inkjet, thermal inkjet, laser marking, thermal transfer and case coding printers. Considering the surface to be printed or marked (e.g. plastic bags, cardboard boxes, cables, heat shrinkable sleeves, pouches, kraft paper bags, PET bottles, metal or almost any other material), Videojet can help you select the ideal lot number printer.

Inks for Videojet continuous inkjet, thermal inkjet, thermal transfer and case coding printers go through a rigorous ink development process that includes extensive analytical instrumentation to aid in substrate evaluation and testing. Sell by dates can be printed on frozen foods, meat packages, baked goods, beverages and snack packaging, as well as pharmaceutical and medical device packaging and more.

In addition to ink-based solutions, a sell by date can be marked on a product with a laser marking system. Using no inks or fluids, lasers can help to reduce a manufacturer’s environmental footprint. The complete line of Videojet CO2, fiber and UV lasers offers a wide range of power and lenses for marking on cases, cartons, metal, glass, cardboard, paper and plastic.

Related Articles

Suggested Solutions

The Videojet 1860 features predictive capabilities that provide up to eight hours of advanced notification of the most common downtime generating faults under normal operating conditions. Print one to five lines of data at speeds of up to 960fpm.

The Videojet 3640 60-Watt CO2 laser marking machine processes complex codes at high speeds and features the industry’s widest mark field. The 3640 is ideal for high-volume applications in the pharmaceutical, tobacco and beverage industries.

The Videojet DataFlex® 6330 includes iAssureTM technology, a built-in code quality checker designed to help reduce waste and rework with no additional hardware or installation. The 6330 is ideal for printing on flexible packaging such as films, pouches and labels.

Case Study

HP Bulmers Bottling Case Study

To meet the need for five lines of text printed at HP Bulmer’s extremely high speeds, Videojet suggested industry-leading the Videojet 1000 Line of continuous inkjet printers designed for 24/7 production and extended run times before requiring maintenance. Bulmers’ codes on beverage cans required a Julian date, a best-before date, a time stamp, and a reference to the production line. Learn more. Learn more….

Utz Quality Foods Case Study

Changing codes when using an old hot stamp machines required costly downtime on an Utz Quality Foods line running 100 packages a minute. Videojet showed Utz the benefits of thermal transfer overprinting including savings on maintenance and less downtime for changing codes. Code changes now require just a few taps of a touch screen. Downtime for code changes has virtually disappeared with Videojet thermal transfer overprinters. Learn more….