Industrial coding and marking solutions for printing on rigid containers

Polyethylene (PE) and High-density polyethylene (HDPE) are among the most common plastics used for rigid packaging. With relatively low surface energy, printing on plastic containers can be challenging but is easily achievable with Videojet solutions.

The Videojet sample lab can provide you with various codes on your plastic packaging using different technologies. They will suggest the optimal technology and help you make an informed decision before you invest in a coding solution.

Videojet offers solutions for coding products that help in the fight against COVID-19 and other health issues. With Videojet printers and lasers, you can print directly on plastic bottles and other plastic containers of disinfectant and cleansers.

There are two primary coding technologies for printing on plastic packaging: continuous inkjet and laser marking .

Continuous inkjet (CIJ) printing on plastic containers

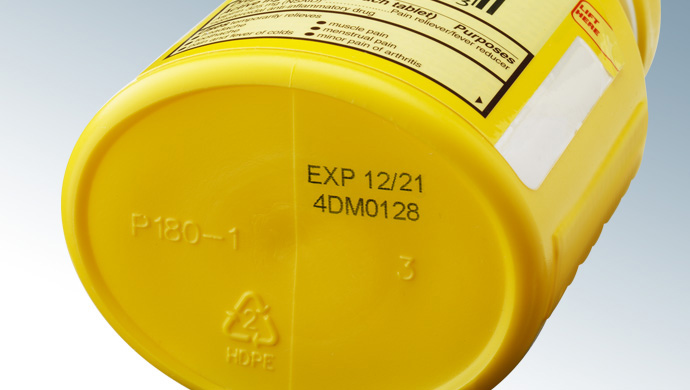

CIJ is an ink-based coding technology which is ideal for curved surfaces and high-speed lines. Excellent code durability can be achieved by matching the ink formulation to the plastic type and product-use environment. With over 640 application-specific fluids, Videojet offer a wide range of ink colors that can provide ideal solution for printing on plastic bottles, plastic pipes and tubes, plastic lids, plastic egg cartons and plastic bags. CIJ is an ideal solution for coding and marking lot numbers, best-by dates and expiration dates on plastic canisters, bottles and containers.

Laser marking on plastic containers

Lasers can provide a high-resolution, permanent code directly on plastic bottles or on labels by causing a material change. Different plastic materials have different reactions to fiber laser; typically a color change or engraving effect is achieved. However, laser coding has a restricted color palette, providing limited contrast on most plastics. Fiber laser systems are an ideal solution for marking on plastic pipes, plastic tubs, plastic bottle closures and plastic automotive parts made of many robust materials such as high-density Polyethylene (HDPE), Nylon, Polyvinyl Chloride (PVC).

- Overview

- Suggested Solutions

- Documents

A variety of Videojet solutions are available for printing on plastic and printing on rigid plastic containers depending on the desired mark effect. Videojet inks for continuous inkjet (CIJ) printers provide quality marks on a wide range of plastics, including high adhesion inks and oil penetrating inks specifically for plastic printing. Laser systems, which deliver permanent but less-noticeable marks, are also an option. Videojet offers a wide laser range including CO2, Fiber and UV to best match laser wavelength with the plastic material.

Optimizing Code Quality on Plastic Packaging

Desired Contrast – Determine if a high contrast code or a less prominent code is more desirable for your product. Expiration information should be clearly visible to the consumer. By contrast, batch/lot information used for tracking purposes may be conveyed with a less obvious code.

Ink Adhesion – Many chemical products contain ingredients that can remove ink codes in the event of spillage. Videojet will help evaluate your product and packaging characteristics to identify the ideal solution for printing on plastic.

Location – Code placement can impact both contrast and permanence of a code.

Perform sample tests – Videojet can help determine if a technology meets your coding needs by testing for contrast, permanence and placement on your plastic containers.

Videojet can help you with printing on plastic

- Identify the ideal coding solution for your product or packaging

- Integrate the solution into your packaging line

- Capture customer attention with printing that aligns to your brand’s image.

- Showcase information that is vital to both customers and distribution partners. •Help you choose from a variety of ink colors to complement your brand and differentiate your SKUs

- Offer solutions designed to eliminate coding errors, jams and misapplied labels on cases

- Help you meet customer, distributor and regulatory requirements

Coding and marking solutions for rigid plastic packaging

- Continuous inkjet (CIJ) printers: Print dates and codes on both flat and curved surfaces of almost any packaging

- Laser marking machines: Mark high-quality, permanent codes on a wide range of product and package surfaces with fewer consumables