Laser Marking Machines

Industrial laser marking systems apply clean, crisp codes on products

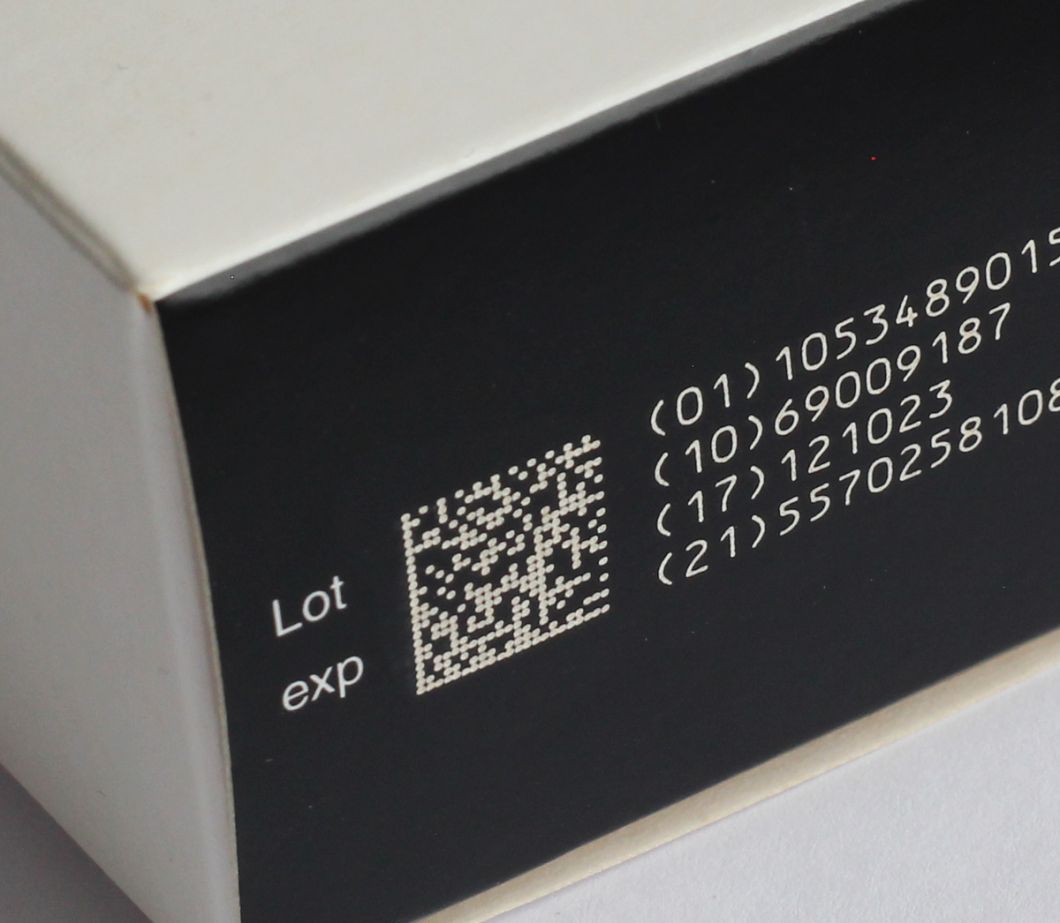

Laser marking is a non-contact printing method that marks or engraves high-quality 1D and 2D barcodes, multiple lines of text, batch numbers, lot codes, dates, logos, and more on products to provide product information and identification, and enable traceability.

Laser marking machines offer advantages such as excellent mark quality, code permanence, and fewer consumables than other coding technologies. The Videojet line of laser marking machines includes CO2 laser markers, fiber laser markers, and UV laser markers in different power outputs to address a range of substrates and applications. In addition, Videojet offers a complete portfolio of laser accessories including lenses and beam turning units that help simplify integration into production lines and help maximize the laser’s performance.

Videojet CO2 lasers

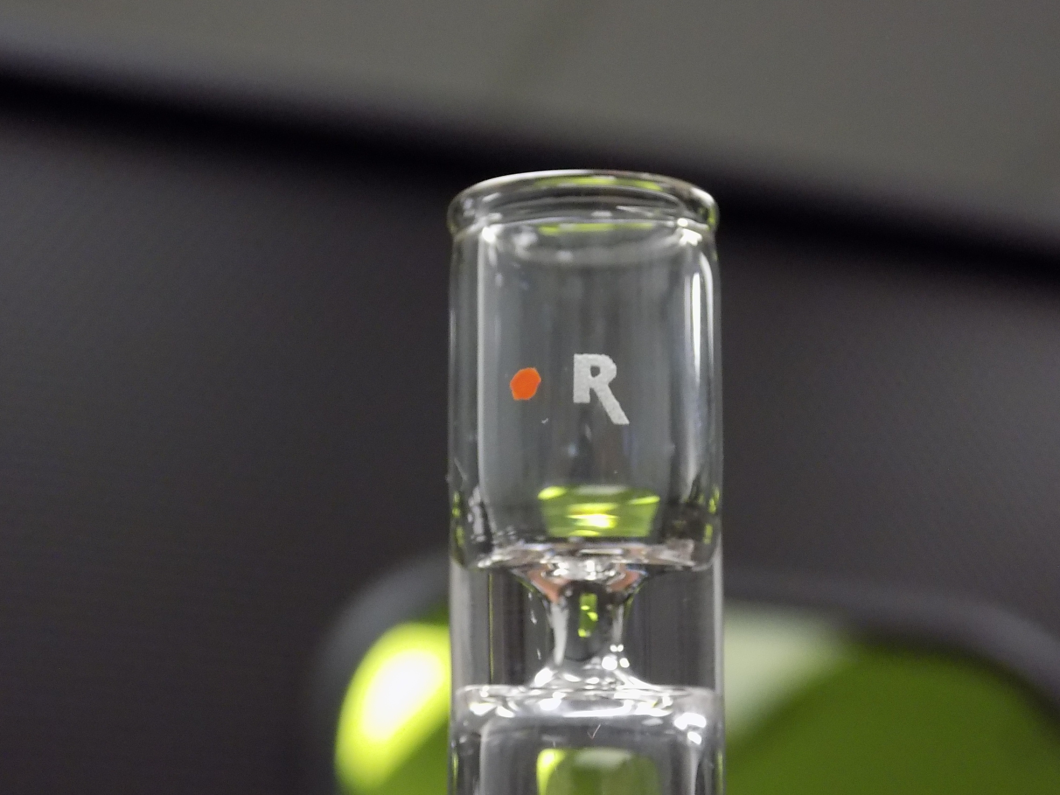

CO2 laser marking systems are a type of laser equipment used primarily for engraving, marking, or etching a wide range of materials. CO2 lasers are particularly effective on non-metal materials like plastic, glass, flexible film, labels, paperboard, and wood. The versatility of the CO2 laser makes it a popular choice for the food, beverage, cosmetics, pharmaceutical, tobacco, and extrusion industries.

Videojet laser marking system

Videojet 3350

Videojet laser marking system

Videojet 3640

Videojet laser marking system

Videojet 3140

Videojet fiber lasers

Providing clear, permanent codes, fiber lasers excel at coding and marking metal including stainless steel, aluminum, brass, and titanium. They are also ideal for many high-density plastic, ceramic, foil, and film applications.

Videojet laser marking system

Videojet 7230/7330

Videojet laser marking system

Videojet 7340/7440

Videojet laser marking system

Videojet Lightfoot™ canning solution

Videojet UV lasers

UV lasers are highly effective at marking on a wide range of materials, including plastic, films and foils, ceramic, and rubber. UV lasers employ a shorter ultraviolet wavelength and lower power compared to fiber and CO2 lasers. With their ability to create high-contrast marks using minimal heat, they are particularly useful for sensitive materials like flexible packaging and glass.

Videojet laser marking system

Videojet 7920

Videojet laser marking system

Videojet 7810

Applications

Laser marking systems provide manufacturers with a safe, ink-free method of marking permanent codes, text, and graphics for product identification and branding. Lasers help serialize items for inventory, generate scannable barcodes and 2D codes for supply chain management, and mark logos and image for brand recognition and anti-counterfeiting. Additionally, they help enable the customization of consumer goods and are essential in the medical industry for marking devices with unique codes.

FAQs

Industrial laser marking uses focused laser beams to permanently etch, engrave, ablate or anneal variable information, such as barcodes, serial numbers, and logos, onto various materials like metals, plastics, and glass. Lasers offers sharp, clear marks that are resistant to wear, ensuring durability and product or part traceability. They can be quickly integrated into production lines for efficient, real-time marking without damaging products. Ideal for manufacturers seeking enhanced product identification and compliance, laser marking can help improve overall efficiency and quality control in the production process.