Labeling Challenges

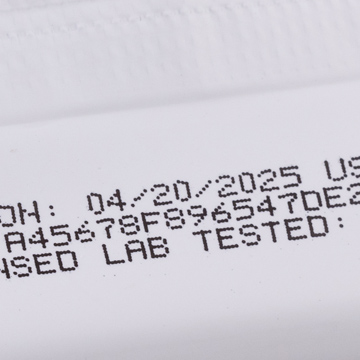

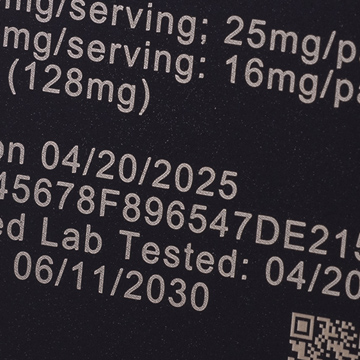

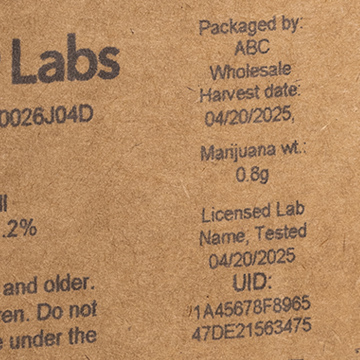

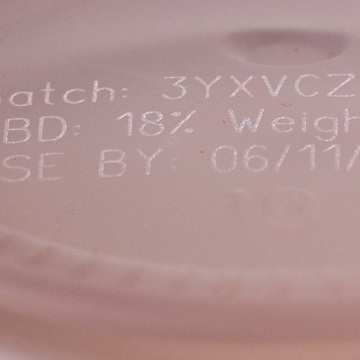

Labeling requirements for cannabis products are strictly regulated and constantly evolving. Processors and packagers of cannabis products are challenged to place vital product information on small, varied packaging surfaces. The wide range of required information such as date codes, batch numbers, serial numbers, weight, strain, testing lab and cannabinoid content poses an additional challenge to processors and packagers.

We are eager to partner with you to address these challenges. Our products will apply the information you need onto virtually every substrate and packaging type. Our printers help you avoid the cost and hassle of printing variable information on your products. This means that you do not have to pre-print information such as weight and strain type on your packaging. It also means that information such as date codes, that vary from batch to batch, can be directly marked on the product without the need for labels.

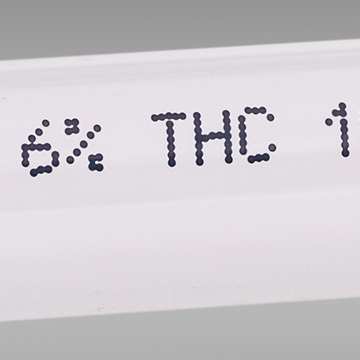

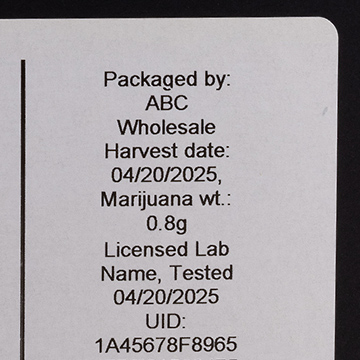

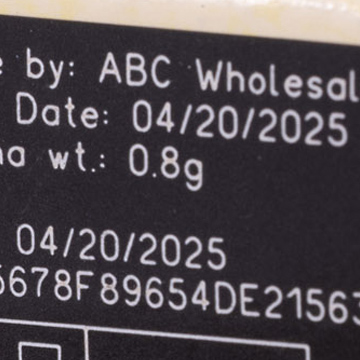

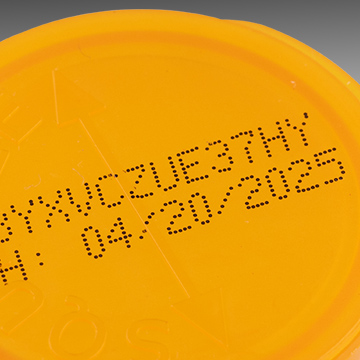

Print Samples

See our product codes on different cannabis applications.

Call (800) 843-3610, chat, or request a call back for a print sample on your cannabis container.

Videojet Solutions

We have a full portfolio of technologies ready to meet the cannabis industry’s varied applications across quality, substrate, and information needs. In addition to our wide product portfolio, we have the right hardware, expertise, and relationships with major packaging automation providers to help ensure our printers will integrate seamlessly into your packaging lines.

| Flexible Film | Glass and Plastic | Metal Containers | Paper and Cardboard | Direct on Edibles | |

|---|---|---|---|---|---|

|  |  |  |  | |

|  |  | |||

|  |  |  |  | |

| |||||

|  |  |  | ||

|

*Typically used to print on a label prior to application

Resources

Expert advice, tips and resources to HELP cannabis manufacturers

Print Sample

Guide

Cannabis OEM Support

FAQs

Depending on the format of the cannabis product, your product packaging might be required to disclose a range of regulated information. Information that is unique to each batch or product is called variable information: for instance, THC potency, batch / lot number and expiration date. Our printers are installed on your production lines and enable you to print product or batch specific information on your product packaging allowing you to change the content of your information / code on the fly. Our printers pair well with your packaging automation lines from a hardware and software perspective.

Variable printing enables simplified SKU management and reduces waste, especially when considering constantly evolving regulations. Ultimately, it lowers packaging related costs. It also helps ensure that published information does not detract from product branding.

With a number of different packaging options, regulatory disclosure requirements and coding technologies to choose from, achieving high quality coding on your production line requires thoughtful planning. Key factors to consider include:

- Types of materials or substrates you’ll be marking

- Desired speed of application or throughput

- Print quality- permanence and readability

- Upfront investment your company is willing to make

- Total cost of operation, which includes cost for service and consumables, such as inks and ribbons

- Whether variable data, graphics and bar codes are needed

Once you know these factors, it will be easier to choose which marking and coding technology is best for your application. Continuous ink jet (CIJ), laser coding, thermal transfer overprinting (TTO) and binary array ink jet printing are all options that have benefits for different applications. We are ready to help you think through the best solution for your production line. Ask your Videojet representative for more guidance, a production line audit or sample testing on your substrate.

Videojet has the right hardware, software, and expertise to help ensure our printers will integrate seamlessly into your packaging lines.

- We partner closely with the major packaging equipment manufacturers (OEMs) to help ensure machine compatibility and ease of integration into all types of packaging equipment.

- Our products not only integrate well with your packaging machinery, but also come with industry-standard software drivers to ensure easy integration into your manufacturing, inventory management, and track and trace setup for operational and state regulatory compliance.

- Finally, the Videojet service and technical support team understands the cannabis packaging and regulatory labelling intricacies and helps ensure that installation is done right the first time. With deep experience supporting customers in other highly regulated verticals such as pharmaceuticals, you can have peace of mind that expertise and support will be available throughout the lifetime of the printer.

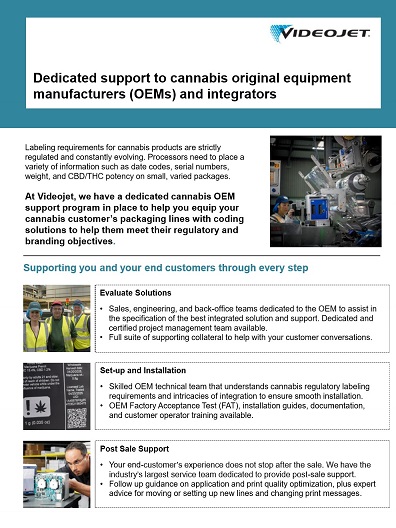

We partner closely with major cannabis packaging equipment providers (or original equipment manufacturers i.e., OEMs) to delivery turnkey solutions to the cannabis industry. Videojet has an industry leading dedicated OEM specific technical team that supports the needs of equipment manufacturers and integrators. This dedicated team provides support for Videojet coding solutions – including and not limited to – equipment evaluation, installation assistance and prioritization along with full implementation of after sales support for the OEM’s cannabis end customer.

Please visit our OEM industry page or contact our OEM specialists at OEM.Marketing@videojet.com for more information.

Contact us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes

(866) 871-3226

inboxusa@videojet.com

Service & Tech Support

(800) 843-3610 Opt #2

Customer Service (United States)

(800) 843-3610 Opt #1

vti.domesticcs@videojet.com

Customer Service (Canada)

(877) 225-2241 Opt #1

vti.canadacs@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search