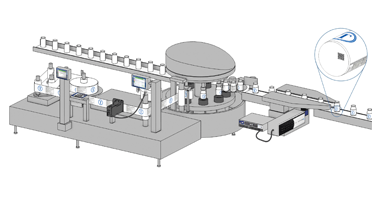

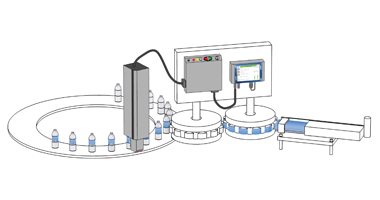

Continuous Inkjet Printing System

An inkjet printing system refers to machines that place marks on products and packaging by projecting droplets through an ink jet onto the surface of the target material, forming letters, numbers, and other codes.

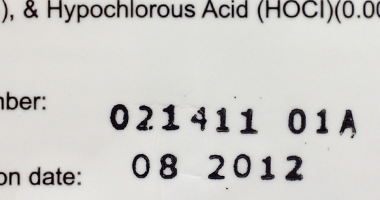

Inkjet coders can print on virtually any substrate, including paper, plastic, wire, cable, metal, resin, glass, and more. Information that is typically printed includes expiration dates, lot numbers, serial numbers, barcodes, and date codes.

The encoder software controls the jet to create these 1D and 2D alphanumeric markings. This allows manufacturers to mark their products and packaging to track products during processing, comply with regulations and facilitate quick recall when necessary. In addition, the fast-drying ability of today’s inks limits the risk of codes rubbing off, ensuring they remain legible during production and distribution.

Videojet inkjet printing systems

- Easy to operate 8” tablet-inspired touchscreen display with SIMPLICiTY™ interface

- Achieve stable performance and reliability across a broad range of operating conditions with the proven Videojet printhead and fluid systems

- One, easy-to-replace Videojet SmartCell™ service module

- All basic I/O ports included

- Maximum line speed: 278 m/min (914 ft/min) printing a single line at 10 characters per inch

- Easy to operate tablet-inspired 10” touchscreen display with SIMPLICiTY™ interface

- Videojet SmartCell™ components help to ensure maximum line productivity and no additional downtime

- Videojet OPTIMiZE provides on-screen alerts with expert diagnostics, analytics and guides to enhance everyday printer performance

- Seamless, non-contact industrial printing for almost any substrate, including flat or curved surfaces

- Enhanced design, easy integration to your production systems, and comprehensive built-in connectivity capabilities

- Reduce downtime with the Videojet MAXIMiZETM advanced diagnostics suite

- Offers built-in monitoring system, smart alerts, on-demand remote technical support, and an advanced automated troubleshooting program

With the ability to place human-readable, scannable, ink-based codes efficiently and reliably, inkjet printing systems have found a place on a very wide range of production lines. These systems are typically used in industries such as food and beverage, as well as pharmaceuticals, automotive parts, and cosmetics.

Many of today’s sophisticated inkjet printing systems incorporate software that not only enables them to print quickly and cleanly, but also alerts operating personnel when ink or solvent supplies are running low. In some cases, the software also allows the inkjet manufacturer to access the unit’s controls for remote adjustments and corrections, reducing the risk of production downtime.

Videojet Continuous Inkjet (CIJ) printers also benefit manufacturers as only 5 minutes of annual preventative maintenance is required by the user, either once a year or when the equipment reaches 3000 hours, whichever happens first. Line personnel can perform this predictable preventative maintenance without the need for a CIJ expert. This helps eliminate surprises that can cause unscheduled downtime and keeps printers running continuously for maximum productivity.

Related Articles