Integrated Solutions for Product Coding, Marking, Printing, Labeling and Stamping

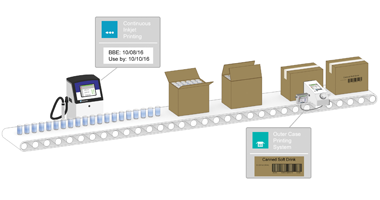

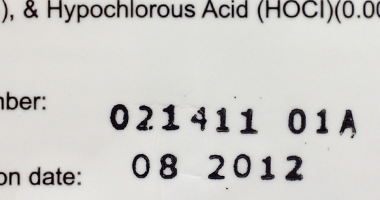

Integrated solutions for product coding, marking, printing, labeling and stamping are designed to place variable data such as expiry dates or batch or lot numbers on products and/or their packaging. This coding enables manufacturers and regulators to verify the authenticity of products. To complete these tasks, it is essential that codes remain readable throughout the life of the product.

These permanent codes can help facilitate the recall of defective or contaminated products, protecting the health and welfare of consumers. The codes can also enable authorities to trace products that have been diverted from their intended receivers, and to identify and remove from distribution counterfeit products before they are delivered to consumers.

Product coding can also provide valuable supply chain and product information for the receiver of transport packaging. The codes enable companies and customers to track products being transported throughout their delivery path, reassuring the receivers that the products will be delivered on time, or alerting them if they will be delayed.

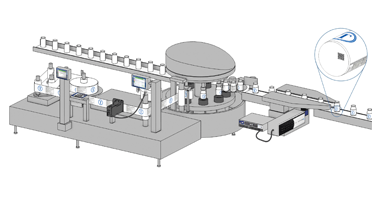

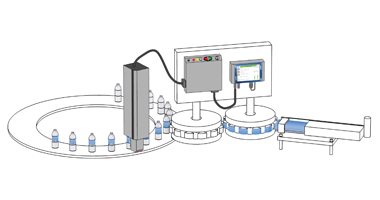

Product coding can be imprinted or stamped directly on products and/or primary packaging using continuous inkjet, thermal inkjet, thermal transfer systems or laser printers. They can also be placed on product and/or packaging by printing the variable codes on labels. Product and primary package labels are usually applied to the product on the production line during the packaging process, and coded after placement.

Continuous inkjet (CIJ) are commonly used to apply codes to paper and other porous and uneven surfaces. Thermal inkjet (TIJ) printers perform well for printing codes on smooth or coated surfaces such as plastic film labels or packaging. Thermal transfer printing (TTP) prints using a film ribbon, and is essential for printing on heat-sensitive surfaces where identification information will be exposed to high heat. Laser printers are used to print or etch codes on metal products, or on metal plates that are then adhered to products.

Today’s advanced code assurance programs, such as Videojet’s CLARiSUITE, store a company’s product codes on a database linked to the company’s production lines. It supplies them to equipment for application to products, then verifies and track the codes as the product proceed through production, ensuring that products leave the facility with proper coding.

Shipping labels, which carry unique product identification and logistical tracking codes, are often printed on demand, using print-and-apply label systems, and then applied to case and pallet loads. Scanning these codes at points during the shipping process provides the tracking data that keeps manufacturers and customers alike apprised of shipping progress.