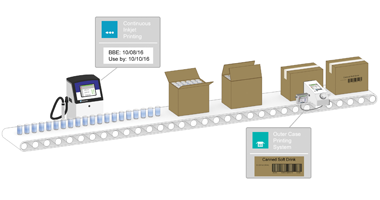

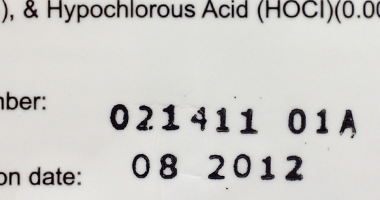

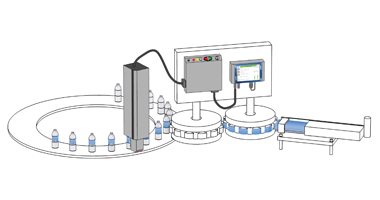

Videojet automatic batch coding machines are used to print batch number, manufacturing date, expiry date, MRP and other such details which provide traceability information about the product.

Importance of Batch Coding:

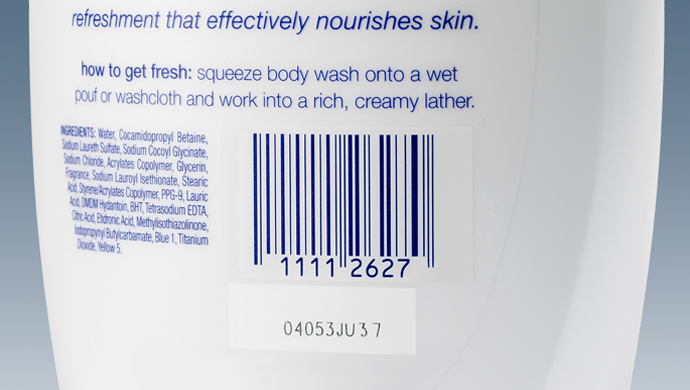

Batch number/Batch code or the lot number should be placed on the product as specified by the country regulations. The number is important as it may be required especially in that case when a product is recalled, or there is a failure with regards to the quality of that batch of products.

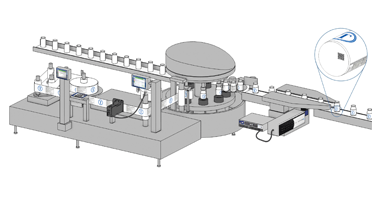

Videojet Automatic Batch Coding machines consist of the following:

- Continuous Inkjet printer/Inkjet Batch Coding machine

- Laser marking machines/Laser Batch Coding machine

- Thermal Transfer Overprinter/TTO Batch Coding machine

- Thermal Inkjet Printer/TIJ Batch Coding machine

- Label Printer and Applicator

Videojet batch coding machines except TTO and TIJ do not come in contact while printing or marking on products. Batch coding machines can print/mark on plain, uneven surfaces and on substrates such as laminated and varnished labels/cartons, polythene bags, pouches, tins, cans, bags, bottles, jars and more.

Videojet batch coding machines can code on virtually any substrate, including the below:

- Automatic Batch Coding on Food Pouches

- Automatic Batch Coding on Baked Goods and Cereal

- Automatic Batch Coding on Beverages

- Automatic Batch Coding on Candy and Confectionery

- Automatic Batch Coding on Dairy Products

- Automatic Batch Coding on Meat and Poultry

- Automatic Batch Coding on Pet Food and Animal Feed

- Automatic Batch Coding on Salty Snacks

- Automatic Batch Coding on Other Packaged Foods

- Automatic Batch Coding on Cosmetics, Personal and Home Care

- Automatic Batch Coding on Electrical Components and Electronics

- Automatic Batch Coding on Wire, Cable and Pipe

Videojet’s Code Assurance solution ensures that the correct code is applied in the correct location on the correct product or packaging.

Customer benefits:

- Drive productivity gains

- Reduce risk, rework and recalls

- Secure and streamline data management

- Protect the brand

Contact a product specialist to get a custom solution for your application.

Related Articles