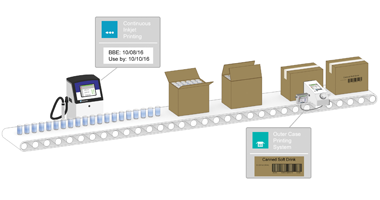

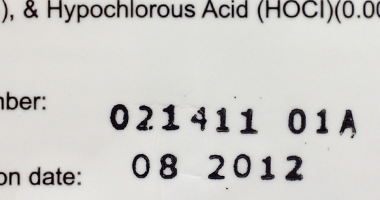

“Best before” dates indicate to purchasers whether food and beverage products or other consumables are safe to buy based on when they were produced and packaged. Many versions of these warnings to consumers are required by regulators and are closely scrutinized by shoppers.

The conditions under which products are packaged can make the clear printing of these messages difficult. This is especially true of beverages and frozen foods, which are processed in environments that can leave moisture on the package surface. Best before date stamp machines must be able to imprint permanent marks regardless of these conditions. In addition, the lines filling these products are quite often operating at high speeds, and any coding equipment must be able to print clear codes at those high speeds.

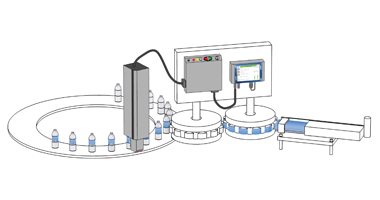

These challenges make the printing of best before dates accomplished most effectively by inkjet printers. These systems can not only print permanent, readable codes at high speeds, they can be programmed to quickly change the date and time information being printed to maintain accuracy.

Today’s efficient date coders often include features that monitor consumables closely to ensure that users are aware when they will need to be replaced. Alerts regarding levels may be sent to the printer’s HMI screen, or sent via text message directly to the line operators or supervisor. This ensures that downtime to replace consumables is kept to a minimum, supporting high line productivity.

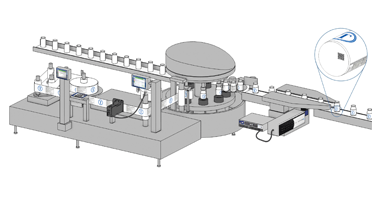

Videojet best before date printers are a natural fit in your production line. They feature a simple, easy to use interface, and can be used on a variety of substrates including glass bottles, plastic, eggs, PET bottles and containers, metal, and cardboard.

Suggested Solutions

The 1880 + enables intelligent plant operations and proactive analytics, such as vital sign monitoring, smart alerts, remote support, and advanced troubleshooting.

The 3640 is a 60-Watt CO2 laser marking system engineered to help address high volume and

highest speed applications in the pharmaceutical,

tobacco and beverage markets. It has been

designed to process complex codes at high

speeds, with the industry’s widest mark field.

Case Study

Videojet 3320 Laser provides high quality and virtually maintenance-free coding on torte boxes at Coppenrath & Wiese. At the location in the plant where the tortes and cakes are packaged, best before date and batch codes are printed on the packaging in high resolution up to 24 hours a day, 300 days a year.

Related Articles