Also see:

Videojet 9560 PL pallet

labeling system

Print & Apply Labeling ![]()

- The Videojet 9560 PL is a reliable, automated pallet labeling system that reduces warehouse costs and mistakes

- Fully automated, it is specifically engineered to function in demanding conditions

- The 9560 PL can cover two or three sides and up to four labels, processing up to 120 pallets per hour across diverse applications

- To help ensure error-free operations, the system verifies label accuracy and reprints incorrect labels as needed

- The 9560 PL also interfaces with warehouse management systems and helps customers adhere to industry regulations

Contact us for New Equipment Sales: (866) 871-3226

Videojet 9560 PL

Specs

| Value | |

| Label Application Method | Telescopic tamp |

| Print Technology | Thermal transfer printing with Intelligent MotionTM Ribbon Drive and Direct Thermal 160mm printhead |

| Ribbon | Width: 5.9 – 6.5” (150 – 165mm) Capacity: Up to 500m, including automatic ribbon save (< 1mm ribbon gap between successive prints irrespective of label size or speed) |

| Print Resolution | 300dpi (200dpi in emulation mode) |

| Print Speed | Up to 15.7in/sec (400mm/sec); speed is dependent on the application |

| Throughput | Up to 120 pallets per hour, based on two labels per pallet |

| Emulations | Zebra (ZPL), Sato (SBPL) and Markem-Imaje (Cimcomms) protocol support |

| Label Width/Length/Capacity | Width/length: 5.9 to 6 .9” / 4.0 to 8.3” (150 to 175mm / 100 to 210mm); A5/A6 Capacity: Up to 330mm spool diameter |

| Interface | CLARiTYTM Controller with interactive on-board video tutorials |

| Connectivity | Ethernet, Power-over-Ethernet, Configurable I/O (24V, PNP and volt free); 8 inputs and 6 outputs USB (for backup/restore and label upload), remote Control Videojet 9560 PL via a web browser |

| Certification | CE, TÜV |

Benefits

Pallet labeling to suit your application

- Rotating tamp pad with wrist joint provides firm label adhesion of up to four labels per pallet

- Label placement on up to three sides of the pallet helps you avoid logistic hold-ups

- Graphical User Interface helps to minimize errors and aids with troubleshooting, while onboard videos help to simplify staff training

- A fully enclosed climate-controlled cabinet helps protects labels from harsh environmental conditions, reducing label warping, deformation, and weak adhesion

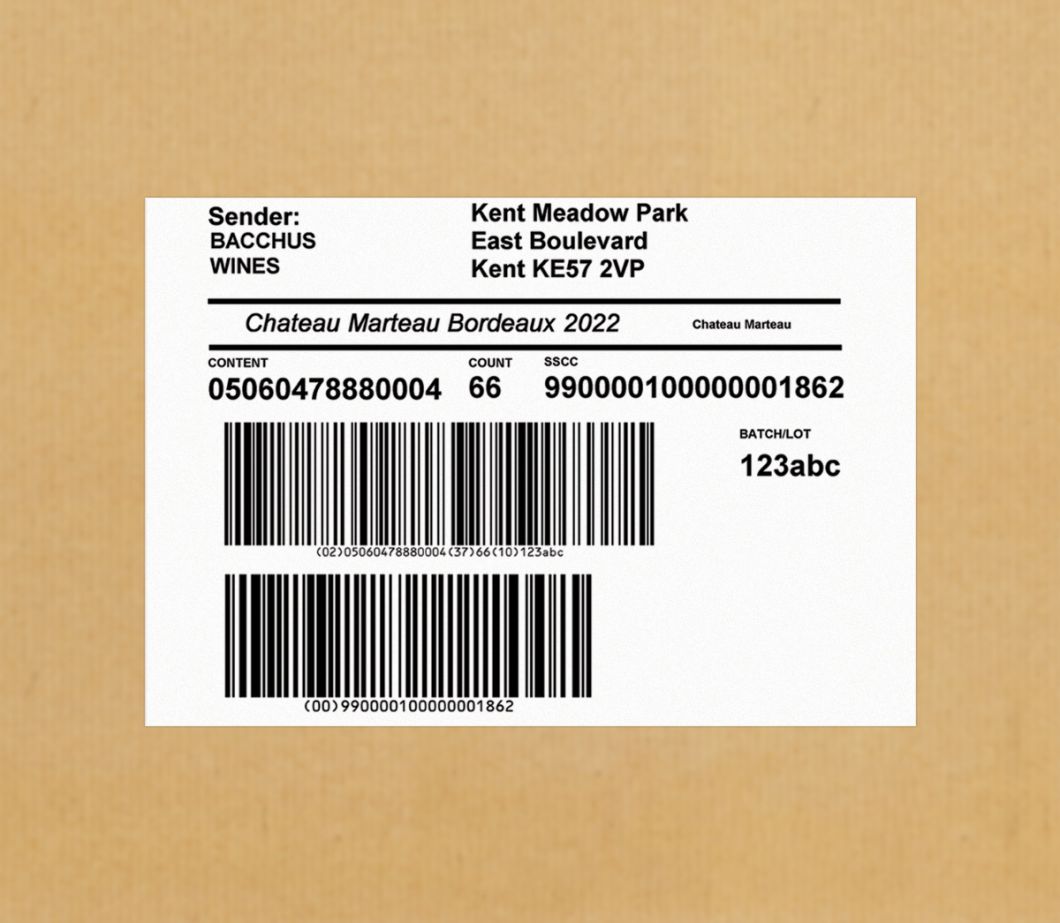

- Thermal transfer labeling does not change color when exposed to sunlight, and can apply identical labels on up to three sides in compliance with GS1 specifications

A rugged and refined design

- Resilient construction and industry-low footprint mean you can put the 9560 PL almost anywhere

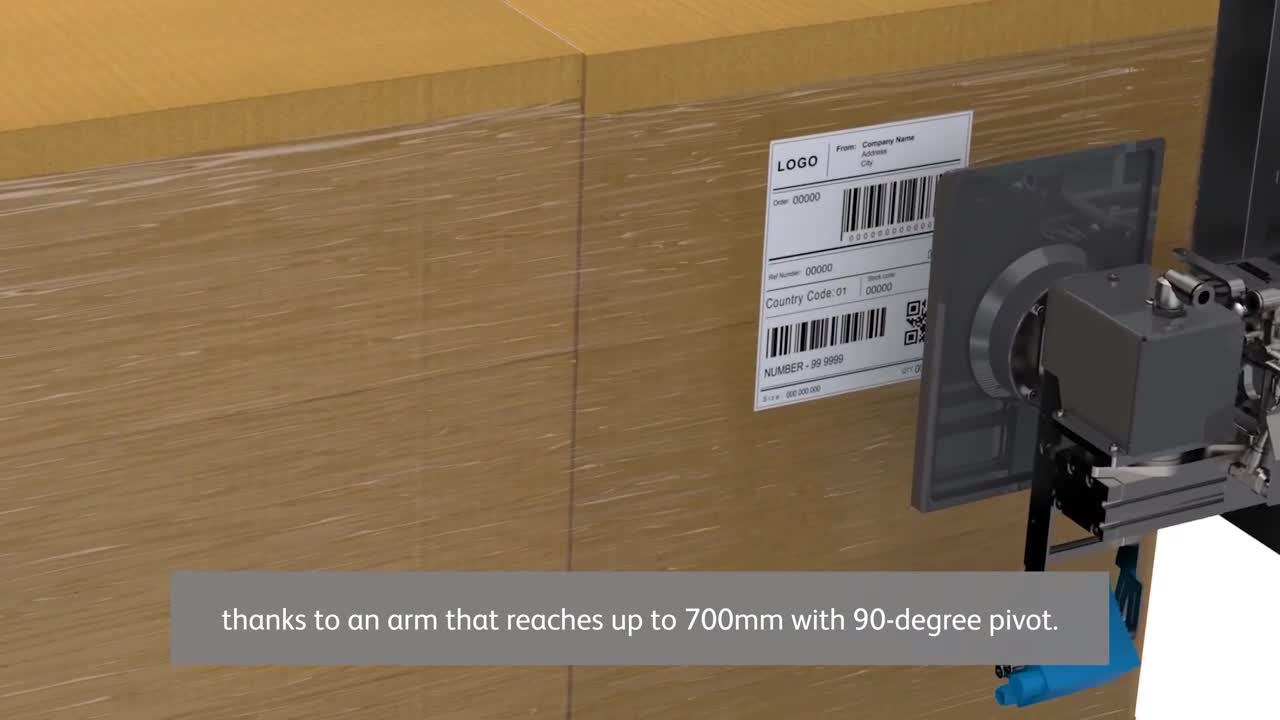

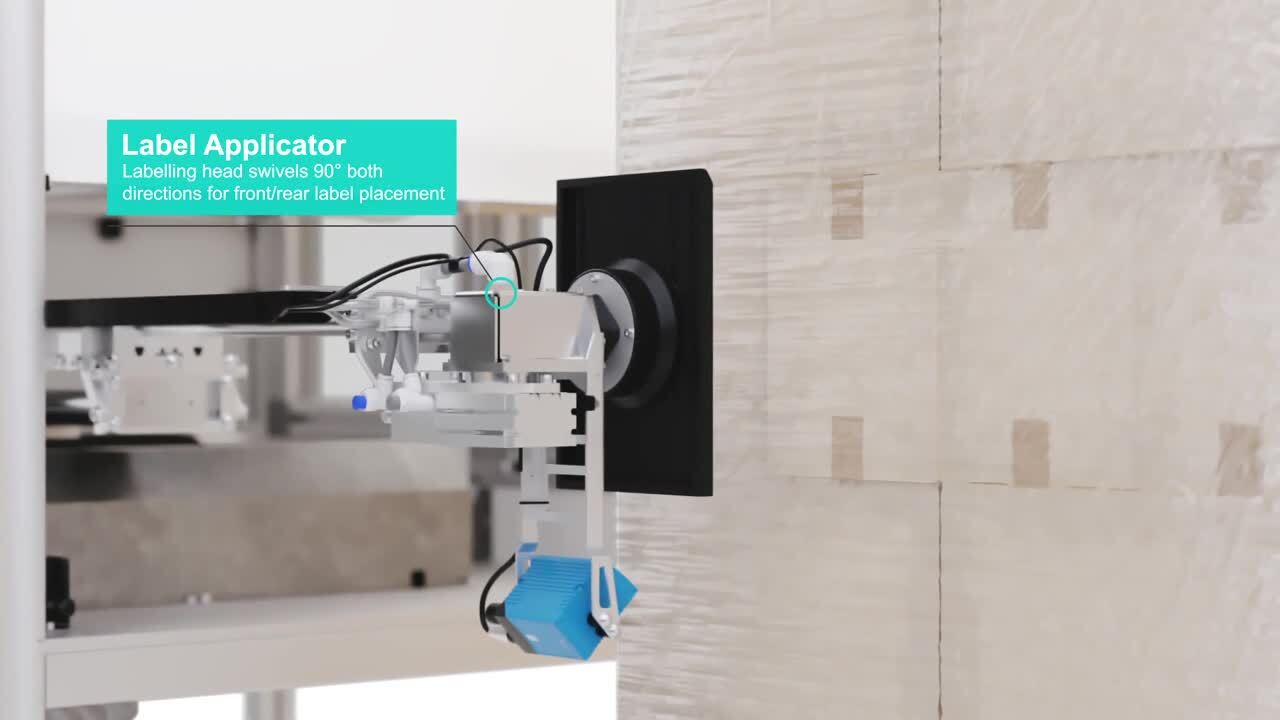

- Three stand height options add flexibility, with a labeling arm that extends up to 700mm beyond the enclosure, and label applicator that

swivels 90o - An integrated bar code scanner checks for label errors, ensures readability, and validates codes

A reliable, next-level solution

- The advanced rotating tamp pad automatically corrects no-read labels caused by dead dots, reducing errors and downtime

- Intelligent Motion™ clutchless, adjustment-free technology enables precise control of all the design elements of the machine

- Label and ribbon replacements can be performed quickly, helping to avoid downtime and lowering the cost of operation

Connectivity-ready for seamless integration

- The 9560 PL offers intelligent I/O capabilities including EtherNet/IP™, PROFINET®, Zebra, and SATO protocols

- VideojetConnect™ software solutions help ensure data integrity, central code management, and easy printer connection across the entire plant

- Industry-leading CLARiTY touchscreen interface delivers intuitive job selection, code assurance, and built-in productivity tools

- VideojetConnect™ Remote Service* provides real-time information on printer issues, helping to monitor equipment status, troubleshoot issues, and improve long-term performance

- Web server capability allows customers to access the 9560 PL via supported web browsers on host computers, with up to five web server sessions per printer

- Available Wi-FI connectivity

*Subject to availability in your country

Supports your sustainability objectives

- Videojet’s comprehensive labeling solutions help you to reduce your environmental impact and optimize your supply chain while maintaining the highest levels of efficiency and reliability

- Intelligent Motion technology eliminates manual adjustments, increasing the overall equipment effectiveness of your line

- The Videojet labeling portfolio provides a range of sustainable labeling options to help you meet constantly evolving regulatory and sustainability requirements

Simple user experience

- Easy-to-navigate user interface with WYSIWYG job print preview

- Self-help onboard videos

Applications

Resources

Documents

Videos

Related products

| Videojet 210 Label Applicator  | Videojet 9550 Print & Apply Labeler  | Videojet 9560 PL Pallet labeling system  | |

| Description | Applies pre-printed adhesive labels to a wide variety of products in low to medium duty production environments. | Print and apply label technology featuring tamp, front-of-pack, and corner-wrap applicator to meet various production needs. | Dedicated automated pallet labeling system that can cover two or three sides and up to four labels, processing up to 120 pallets per hour. |

| Printing technology | N/A | Thermal Transfer with 53mm, 107mm, and 160mm printhead versions | Thermal Transfer with 60mm printhead |

| Throughput | Up to 150 packs per minute | Up to 2 pallets per minute | |

| Max Line Speed | 30m/min | 24m/min | |

| Minimum Label Size (Width x Length) | 12 x 12mm | 40 x 50mm | 150 x 100mm |

| Maximum Label Size (Width x Length ) | 104 x 500mm | 165 x 500mm | 175 x 210mm |

| Capacity | Up to 300mm spool diameter (optional 400 mm) | Up to 400mm spool diameter (typically delivers over 9000 typical GS1 bar code labels per roll) | Up to 330mm spool diameter |

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes![]() : (866) 871-3226

: (866) 871-3226![]() : inboxusa@videojet.com

: inboxusa@videojet.com

Service & Tech Support![]() : (800) 843-3610 Opt #2

: (800) 843-3610 Opt #2

Customer Service (United States)![]() : (800) 843-3610 Opt #1

: (800) 843-3610 Opt #1![]() : vti.domesticcs@videojet.com

: vti.domesticcs@videojet.com

Customer Service (Canada)![]() : (877) 225-2241 Opt #1

: (877) 225-2241 Opt #1![]() : vti.canadacs@videojet.com

: vti.canadacs@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search