Also see:

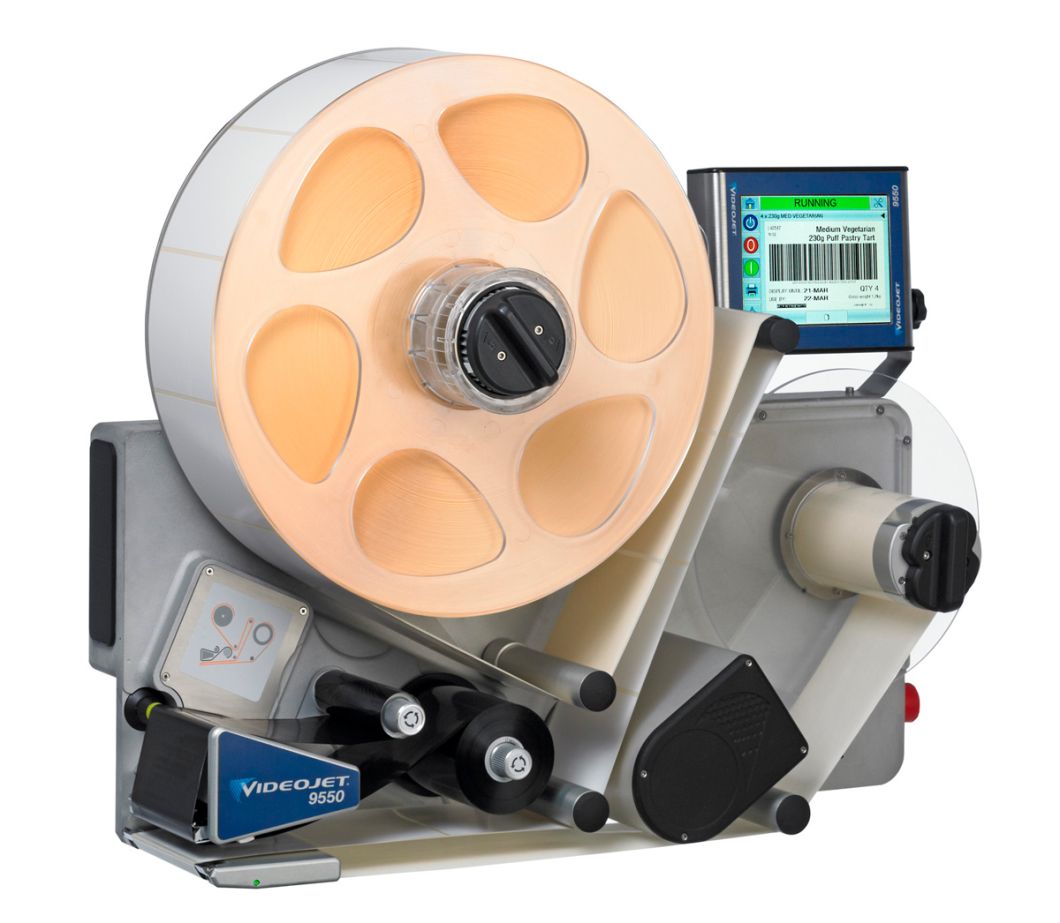

Videojet 9550 Print & Apply Labeling Machine

Print and Apply Labeler ![]()

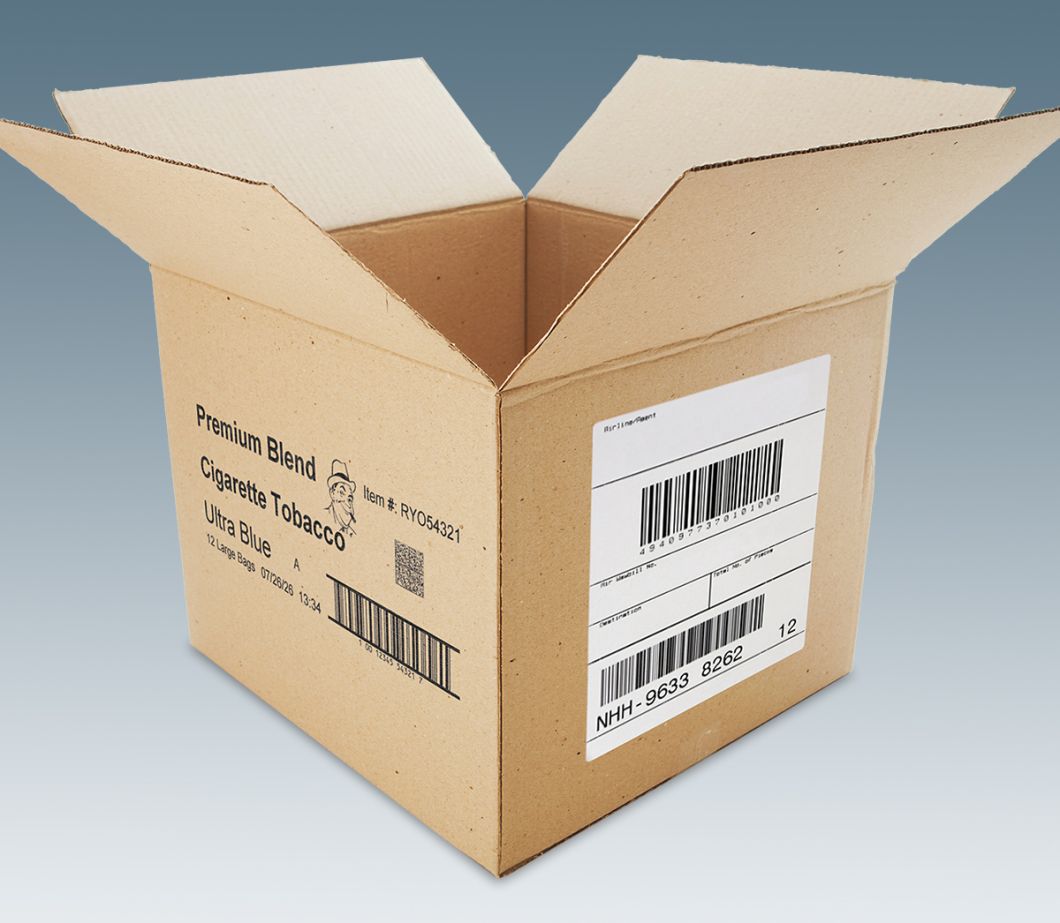

Print & apply labeling solution for cartons, cases, pallets and shrinkwrap

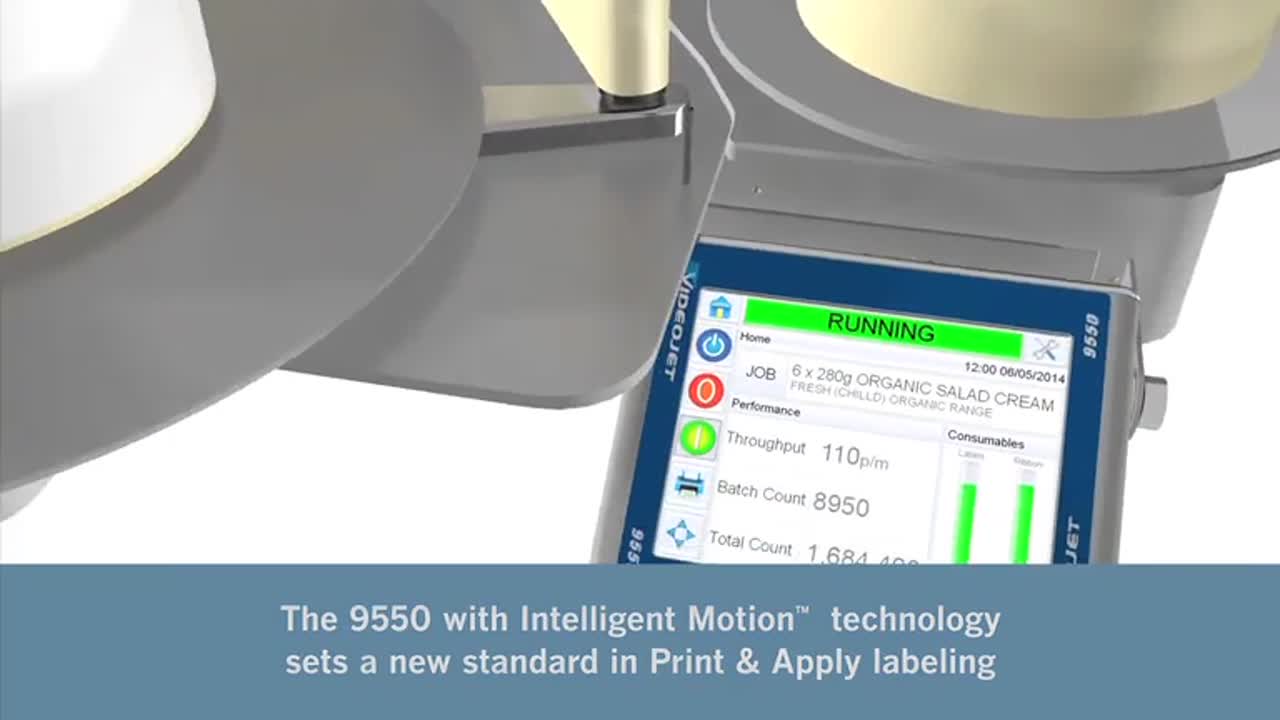

The 9550 Label Printing Machine with Intelligent MotionTM is a smarter print and apply labeler that targets zero unscheduled downtime and reduces costs and errors in case coding operations. Automatic, precise control of the entire system together with Direct Apply label placement, provides the most efficient and reliable industrial labeling machine.

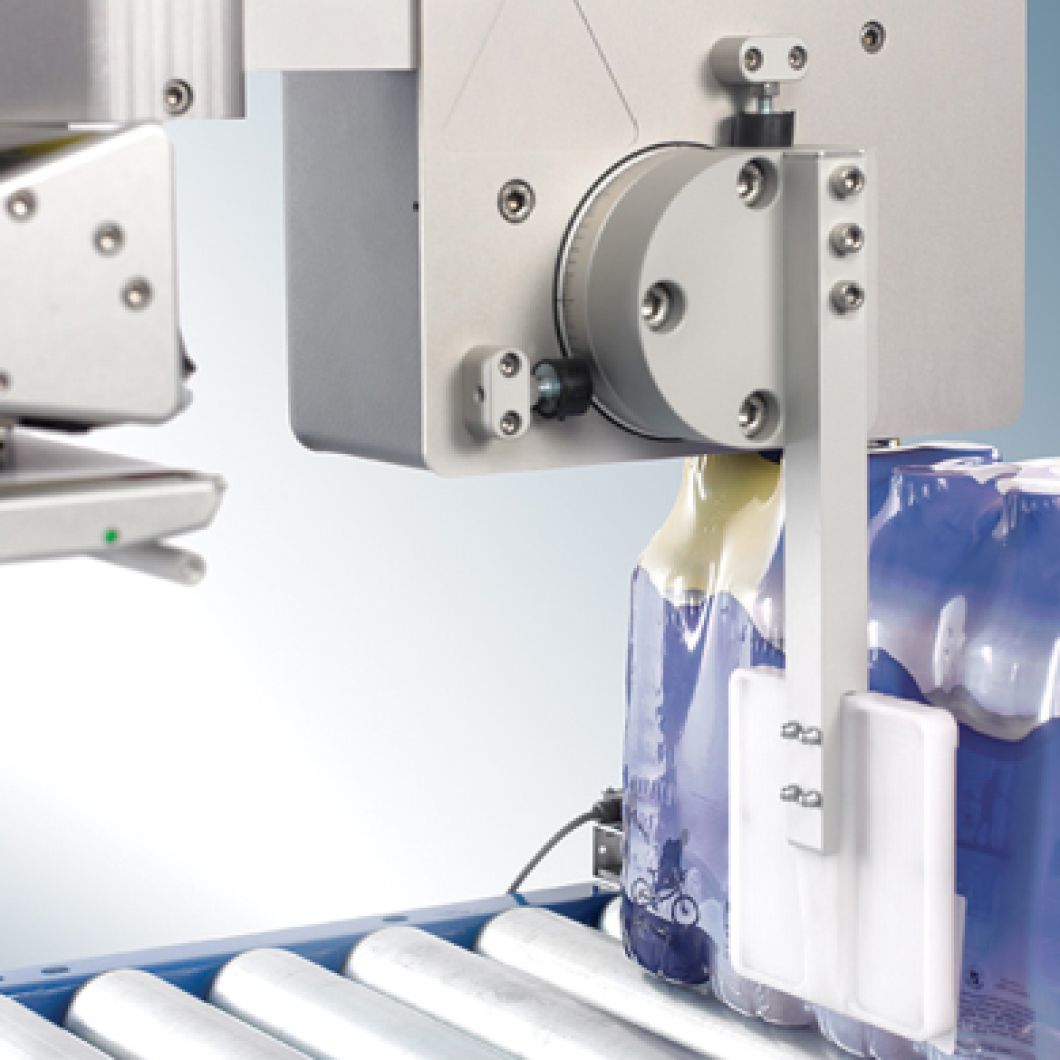

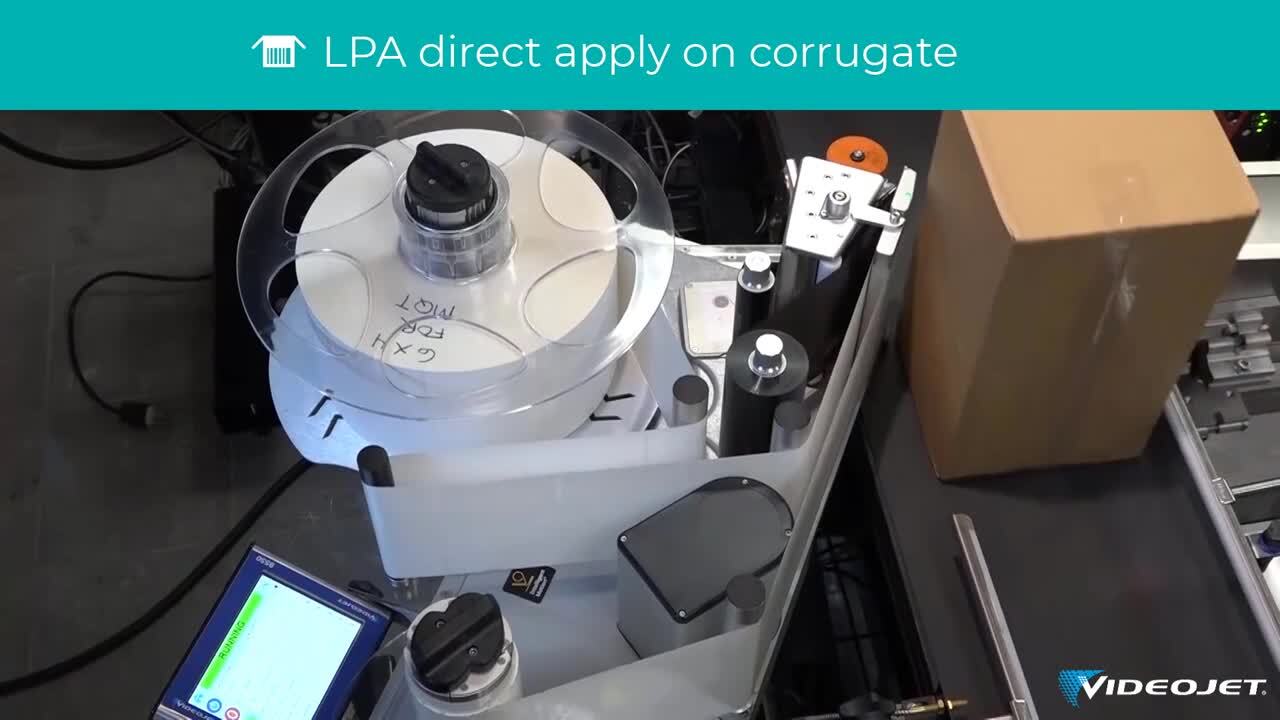

This Videojet print and apply labeling machine can aid with high contrast bar codes and other production information on various substrates like shrink and stretch wrap, cardboard boxes, egg cartons and cases.

In addition to the Videojet 9550 with Direct Apply™, Videojet offers 9550 units that feature a tamp applicator, a front-of-pack applicator or a corner-wrap applicator.

Download the 9550 Print & Apply Labeler brochure or contact a Videojet labeling machine expert for a free consultation: (866) 871-3226

And with optional VideojetConnect™ Remote Service, your team can access Videojet experts to help improve productivity and troubleshoot potential issues in ways that other printers can’t.

Contact us for New Equipment Sales: (866) 871-3226

Videojet 9550 LPA

Specs

| Value | |

| Label Application Method | Direct Apply (standard) Other optional applicators: Telescopic tamp, Front of Pack, Rear of Corner Wrap |

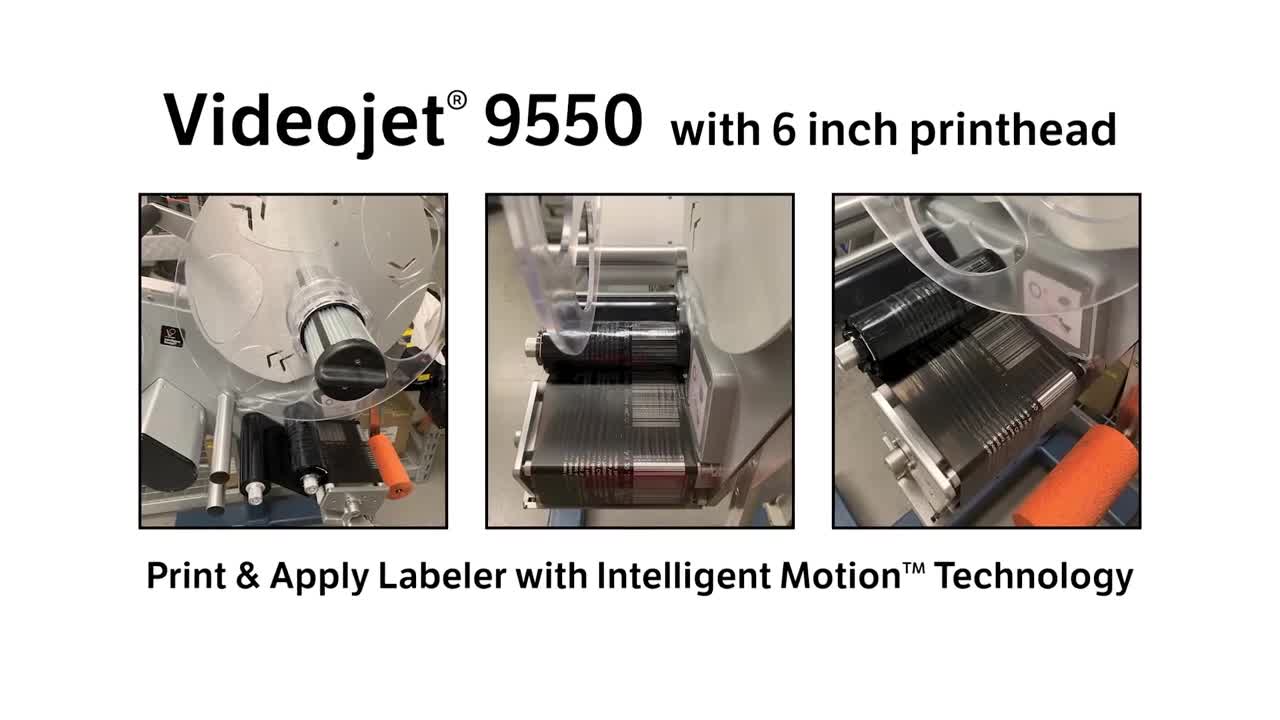

| Print Technology | Thermal Transfer printing with Intelligent Motion™ Ribbon Drive or Direct Thermal Printing with 2” (53mm), 3” (76mm), 4” (107mm) and 6” (160mm) printhead versions |

| Ribbon Width | Minimum 2.2” (55mm), 3.0” (76mm), 4.3” (110mm) (standard) and 6.4″ (162mm) / Up to 830m |

| Print Resolution | 300dpi (200dpi in emulation mode) |

| Print Speed/ Throughput | <4” label width up to 500mm/sec in standard mode and up to 750mm/sec in high speed mode >4” label width up to 400mm/sec in standard mode up to 150 packs/minute with a 4”x6” label dependent on label size and application |

| Emulations | ZPL, SBPL |

| Label Width/Length/Capacity | 1.6” to 6.5” / 2.0” to 12.9” (40mm to 165mm / 50mm to 330mm) spool diameter |

| Interface | CLARiTY Controller – A single intuitive screen with on-board label database and video tutorials |

| Connectivity | Ethernet, RS232, Configurable I/O (24V, PNP and volt free) and USB |

| Certification | CE and TÜV |

Benefits

Uptime Advantage keeps productivity up and costs down

- Zero mechanical adjustments during day-to-day operation

- Optimizes maintenance labor by eliminating more than 80% of wear parts

- Never miss a label, with self-adjusting label placement to accommodate varying line speeds, throughput and package sizes

- Improve throughput during build-back with Direct Apply labeling up to 150 packs per minute for typical 4”x6” labels

- Additional applicator models (Telescopic-Tamp, Front of Pack and Corner Wrap) to fit a range of applications

Simple Usability keeps operators focused on production, not on the printer

- Virtually eliminate label jams and simplify set-up with Direct Apply for mainstream top or side applications

- Minimize misapplied and snapped labels with on-demand Direct Apply using no plant air

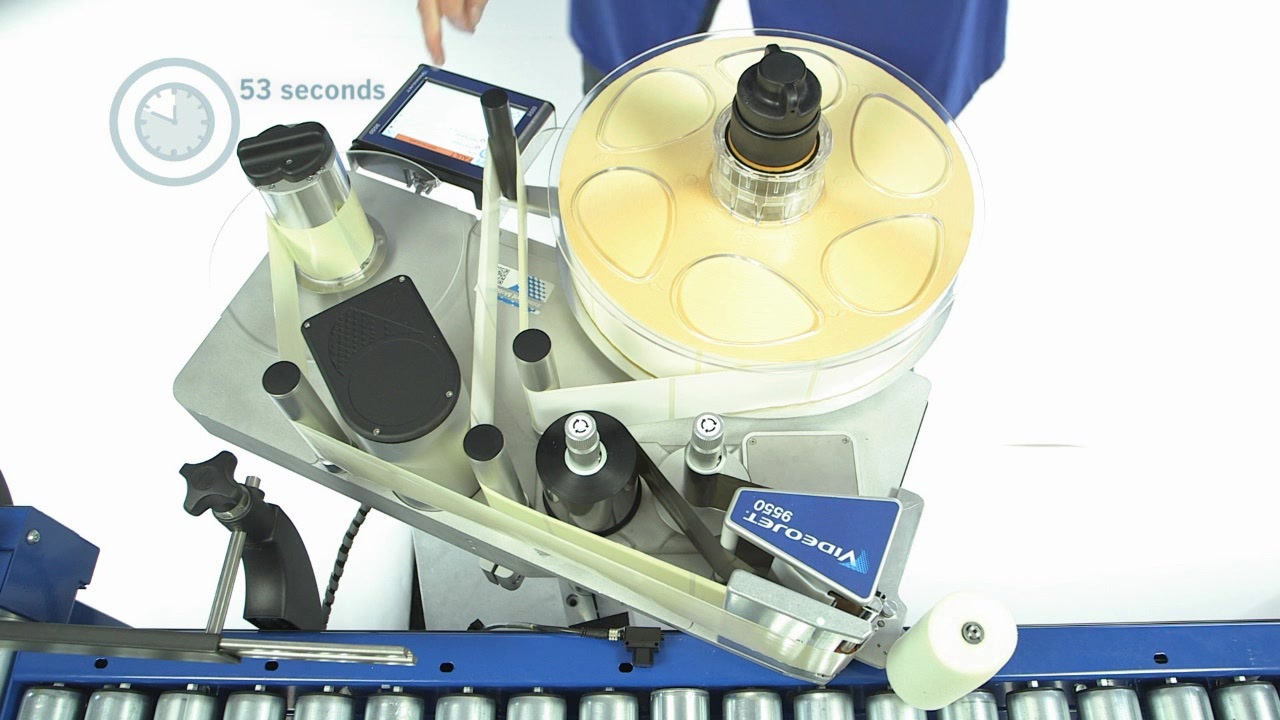

- Perform label and ribbon changes in less than 60 seconds through simple web path

- Quickly check status and select jobs with single, intuitive interface that makes operation easy

CLARiTY interface reduces operator errors, ensuring products are coded correctly

- Virtually eliminate coding errors with built-in Code Assurance software features

- Minimize operator touches with on-board label database for accurate job selection

- Automate barcode creation by linking data from multiple text fields

- On-screen diagnostics track performance and help achieve sustainable OEE improvements

Applications

Resources

Documents

Videos

Related Products

| Videojet 210 Label Applicator  | Videojet 9550 Print & Apply Labeler  | |

| Description | Applies pre-printed adhesive labels to a wide variety of products in low to medium duty production environments. | Print and apply label technology featuring tamp, front-of-pack, and corner-wrap applicator to meet various production needs. |

| Printing technology | N/A | Thermal Transfer with 53mm, 76mm, 107mm, and 160mm printhead versions |

| Throughput | Up to 150 packs per minute | |

| Max Line Speed | 30m/min | |

| Minimum Label Size (Width x Length) | 12 x 12mm | 40 x 50mm |

| Maximum Label Size (Width x Length ) | 104 x 500mm | 165 x 500mm |

| Capacity | Up to 300mm spool diameter (optional 400 mm) | Up to 400mm spool diameter (typically delivers over 9000 typical GS1 bar code labels per roll) |

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes![]() : (866) 871-3226

: (866) 871-3226![]() : inboxusa@videojet.com

: inboxusa@videojet.com

Service & Tech Support![]() : (800) 843-3610 Opt #2

: (800) 843-3610 Opt #2

Customer Service (United States)![]() : (800) 843-3610 Opt #1

: (800) 843-3610 Opt #1![]() : vti.domesticcs@videojet.com

: vti.domesticcs@videojet.com

Customer Service (Canada)![]() : (877) 225-2241 Opt #1

: (877) 225-2241 Opt #1![]() : vti.canadacs@videojet.com

: vti.canadacs@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search