Various types of laser marking systems are used to print or etch marks on metal surfaces. These permanent codes are essential to ensuring that genuine products and parts can be quickly identified. They are used in aerospace and automotive industries, as well as on consumer packaging such as beverage containers and pharmaceutical product packaging.

Laser etching machines include a variety of CO2, infrared, UV, and fiber laser systems. Since metals are heat-resistant materials, marking metals originally required high-density laser irradiation. These systems mark surfaces in three ways: laser marking, laser etching, or laser engraving.

Typical metals for laser printing include:

- Anodized aluminum

- Stainless steel

- Coated metals

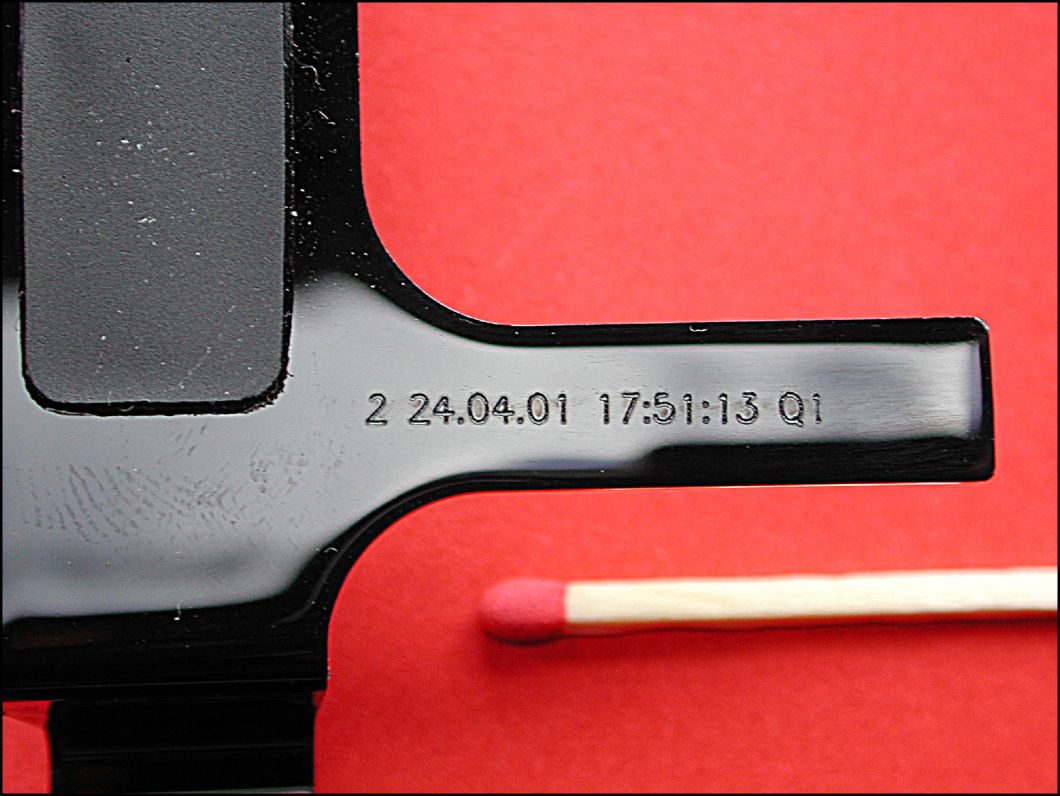

Fiber laser marking is the most often used for placing critical marks or codes on stainless steel surfaces. These higher power systems mark identification codes directly on stainless steel parts and on larger products by etching or engraving the surface. These codes may be numeric, alphanumeric, 2D or conventional bar codes.

CO2 laser marking systems using shorter wavelengths than the traditional CO2 laser wavelengths can be used to create marks on metal surfaces such as anodized aluminum. The process removes the color from the aluminum surface, exposing the bare metal surface beneath, creating precise characters for coding.

Laser systems are also used to mark surfaces that have been previously prepared by being coated with enamel paints, removing the paint surface to create alphanumeric characters and 2D codes in the exposed metal surface. This process has the advantage of using very low power lasers, reducing costs and speeding production. It also, because of its low power usage, produces little or no fumes or residues, creating a safe environment for workers.

Pre-coated and spray-coated surfaces have also been developed for use in laser engraving metals. These coatings apply a coating that is visible to the laser beam, which fuses the coating to the substrate as the beam passes. These coatings, when touched by the laser beam, change the surface of the metal to a different color (often black, brown, or grey) to create the desired mark.

The Videojet Advantage

Mark quality and permanence, high uptime, and simplified maintenance are but some of the reasons to select laser marking technology for your operations. But not all lasers and not all laser suppliers are the same. Specifying a successful solution starts by working with the right partner – one who brings the broadest range of tools, application knowledge, and field support. Since 1985, Videojet has been working continuously on laser innovation to bring the broadest substrate and application coverage possible to the packaging industry.

Talk to Videojet to choose your metal laser printer (833) 270-0843

Metal Laser Printing is an ideal solution for:

Customer Feedback:

“Aerospace requires 99% of parts to be marked, which was previously done by hand stamping. A Videojet system has saved a great deal of time in the marking process.”

– IT Director, Small Business Aerospace Company