Laser etching is a non-contact technology used to mark or engrave high quality 1D or 2D barcodes, multiple lines of text, batch numbers, lot codes, logos, traceability codes and other essential information on various types of products and packaging for identification purposes. The etching process alters precisely targeted areas of material on the package or product surface to create a highly visible code in the material directly. This process eliminates the possibility of important printed information being blurred or obscured during or after application and becoming unreadable.

Laser etching machines are used in many industries, including aerospace and aircraft, automotive, extrusion, pharmaceuticals, and others. Laser etching machines can mark a wide range of materials, including metals, coated or painted metals, glass, and multiple types of plastic. Different materials require lasers of different power levels, and choosing the correct power has a direct effect on the result. It is essential for the user to collaborate with the laser system manufacturer to obtain the most effective system. Laser-etching may also require the addition of a fume extraction system to protect production line workers.

Advantages of laser etching machines

Laser etching offers several important advantages over other marking technologies, including extremely consistent marking quality and permanent marking. For various manufacturers, another significant advantage is that laser etching systems can operate at very high speeds, which directly affects productivity, and can mark targets as they move along a production line, guided by beam controllers. In addition, since no inks or solvents are involved, the need for fewer consumables directly affects production costs, eliminating the need for ink supply replacement, reducing maintenance requirements, and significantly lowering the user’s impact on the environment.

Different types of laser etching machines

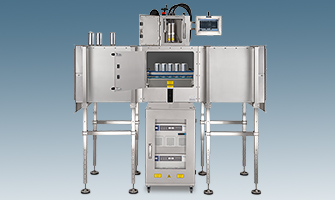

Laser etching machines include a variety of CO2, Fiber, and UV laser systems. Videojet offers laser machines in different power outputs to address etching on a variety of substrates. In addition, the availability of a variety of laser accessories, including lenses and beam directing units, simplifies the integration of a laser etching machine into a range of production line configurations and maximizes the laser’s performance.

The flexibility, precision and permanent result of laser marking is especially important to the packaging of pharmaceuticals and tobacco products, where unique serialized codes are required to ensure authenticity and tamper-proofing and to facilitate traceability. Laser etching machines offer highly reliable product marking on high-speed beverage production lines. The wide range of available CO2 laser lenses, powers and technology types enables successful laser etching on glass and most plastics. Fiber lasers are ideal to mark on aluminum cans, delivering clear, permanent codes on a wide variety of can colors.

View our Laser coding and marking Print Sample Guide or talk to our laser marking specialist at (833) 270-0843.

Suggested Solution

3350 Laser Marking Machine – Customer testimonial

Related Articles