Also see:

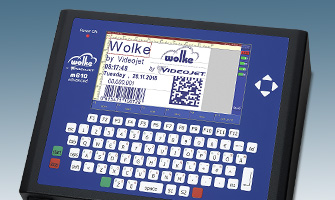

Wolke m610® OEM Thermal Inkjet Printer

Thermal Inkjet Printer ![]()

The Wolke Thermal Inkjet Printer for Pharmaceutical Track and Trace Applications

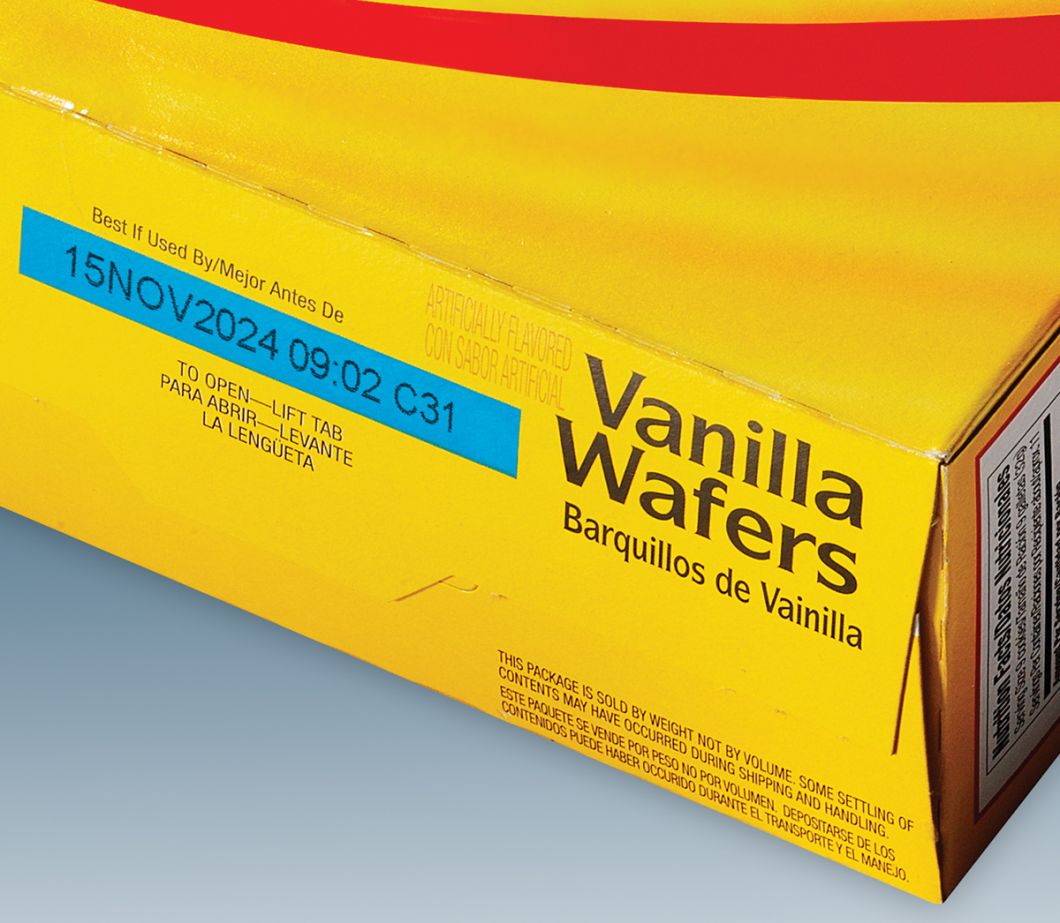

The Wolke m610 oem thermal inkjet (TIJ) printer establishes the gold standard for track and trace applications. Intelligent in design and practical in build, the m610 oem delivers breakthrough integration versatility combined with the industry’s most powerful data handling and global track and trace capabilities. Specifically designed to meet present and future serialization requirements in pharmaceutical packaging applications.

Contact us for New Equipment Sales: (866) 871-3226

Wolke m610 OEM TIJ Printer

Specs

| Value | |

| Maximum Print Resolution | 600 x 600 dpi |

| Print Speed(1) | Up to 300 m/min (984 ft/min) |

| Bar Codes | Multiple linear and 2D bar codes including DataMatrix, QR, GS1, PPN, HIBC |

| Single Printhead Print Height | 12.7mm (0.5in) |

| Maximum Number of Printheads | Connect up to 6 |

| User Interface | 3.5” resistive display; auto-rotates in any orientation |

| Data Interfaces | 24V DC I/O connector, Ethernet, TCP/IP, FTP, USB-A |

| Environmental Protection | IP20 (controller) |

(1)Line speed dependent on selected print resolution

Benefits

Powerful data handling for serialization requirements

- Secure ultra-fast processing of 20 unique records per second, including 2D DataMatrix and GS1 128 bar codes

- Powerful processing hardware with formidable data buffer for serialized record management

- Validated Wolke remote commands and data handling commands

- Unicode TrueType® fonts for global projects

- Asynchronous communications practices alleviate network traffic

Ultimate flexibility when integration matters

- Up to 60% smaller than comparable TIJ controllers with 24V DC power for easy cabinet installation

- 18 different mounting options in various orientations, including flush-mount or DIN rail

- Connect up to six printheads and run any four simultaneously for switching between print locations without mechanical adjustment

- Printer operations and settings managed exclusively via the host packaging line HMI

Advanced innovation drives productivity

- Perpetuo Print Mode™ extends production runs or allows ink replenishment without stopping the line

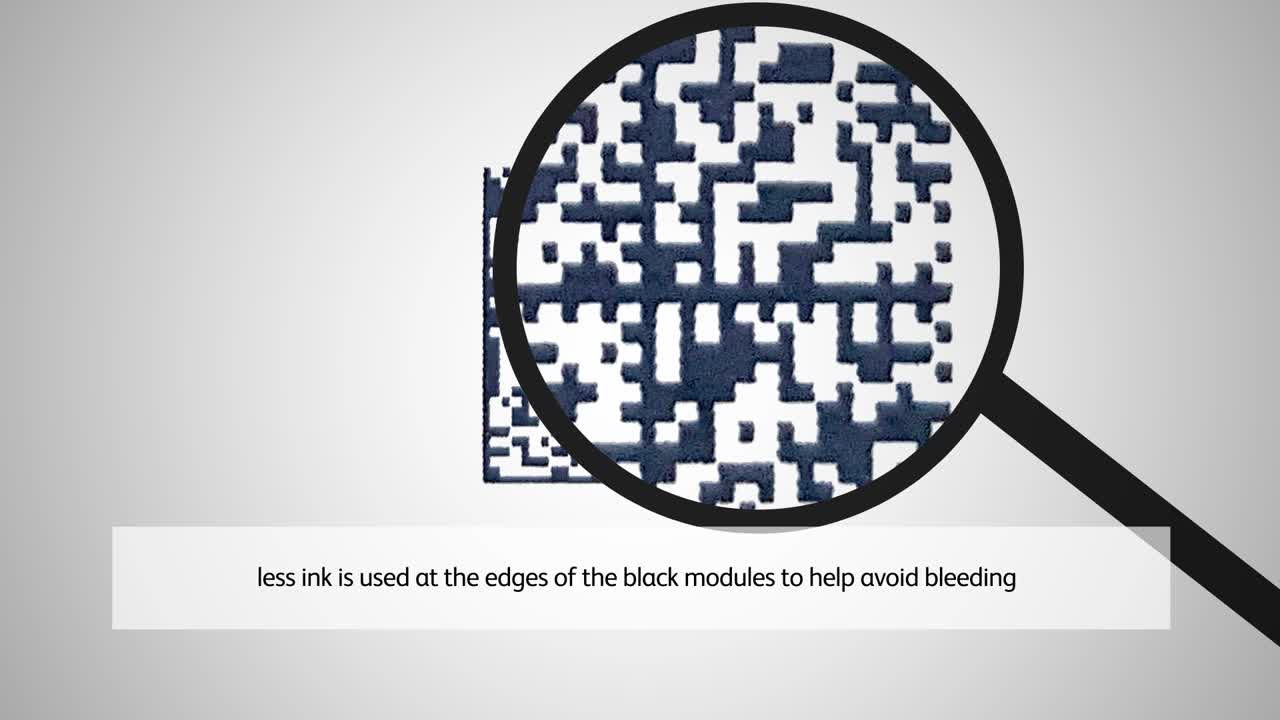

- Dynamic Print Intensity™ allows different DPI resolutions to be set for bar codes and text within one printhead, optimizing ink consumption

- Specialized portfolio of Wolke TIJ inks optimize critical applications

“The blister application at Medreich PLC is perfect for the m600 with Flex Solvent as the adhesion is superior to anything else comparable on the market and we’ve managed to achieve a much better contrast code for machine readability.”

Jake Barnes – Technical Sales Manager, Medreich PLC (case study)

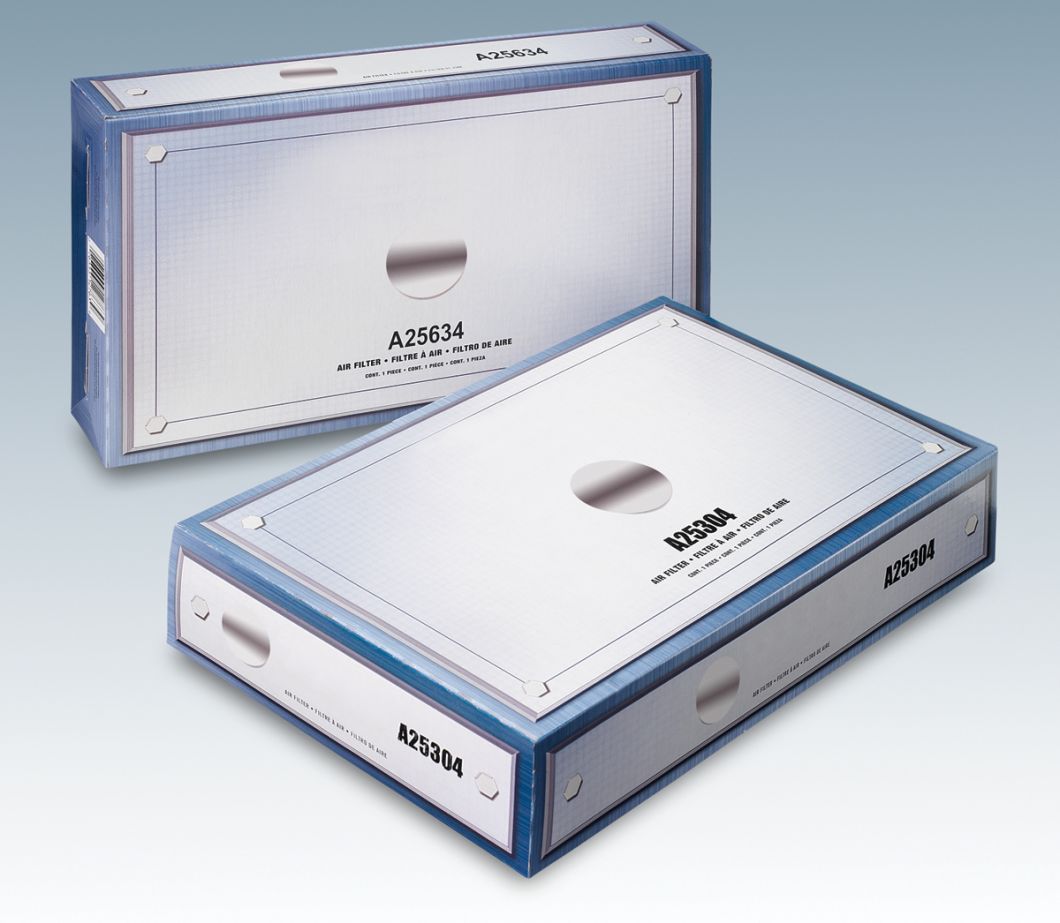

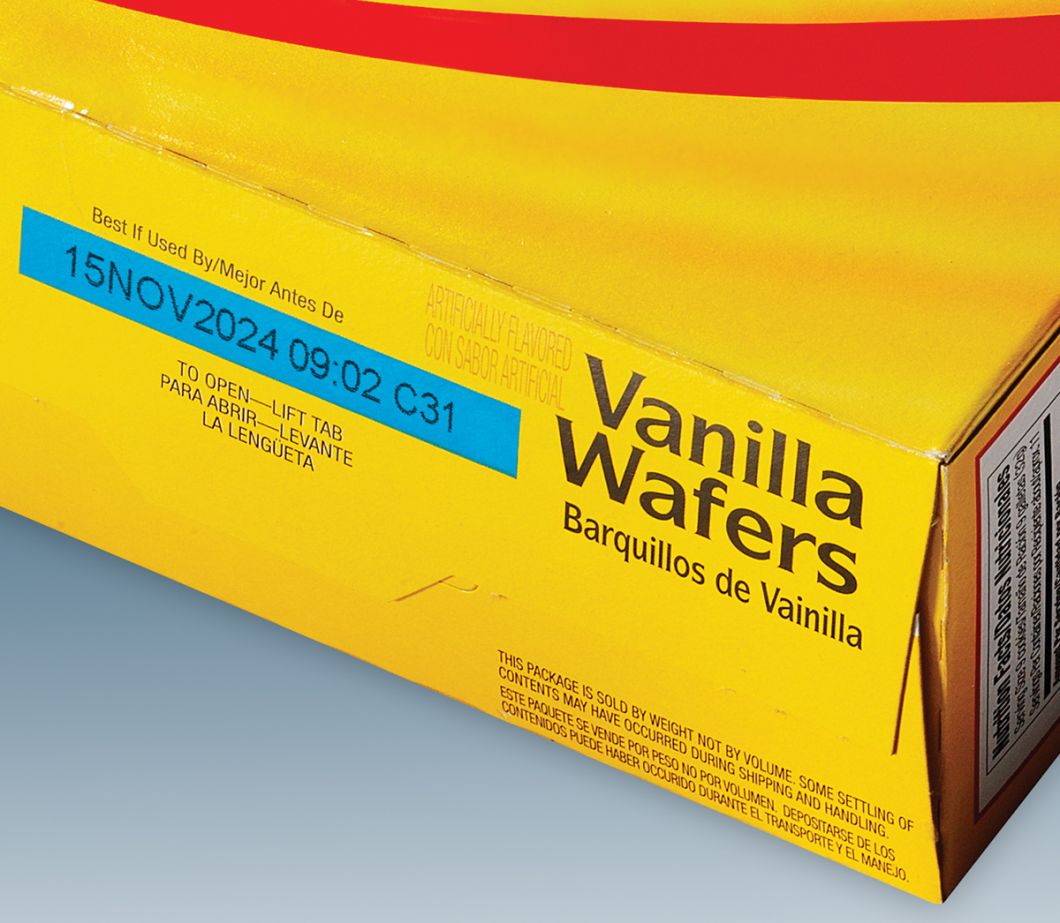

Applications

Resources

Documents

Videos

Related Products

| Videojet 8520 and Wolke m610 touch  | Wolke m610 Advanced  | Wolke m610 OEM  | |

| Description | Most popular Videojet TIJ printer with a great balance of speed and performance. | Entry-level TIJ printer suitable for both stand-alone operation and fully integrated into production line equipment. | The fastest and smallest of comparable TIJ printers for a powerful, lightweight and versatile solution favored by our OEM partners. |

| Shared Specs | – Ideal coding and marking solution for a range of primary and secondary marking applications – Max print resolution of 600 x 600 dpi | ||

| Print speed | 1.5 – 109 m/min (5 – 360 ft/min) | 1.5 – 75 m/min (5 – 250 ft/min) | Up to 300 m/min (984 ft/min) |

| Bar code printing | EAN8, EAN13, UPC-A/E, CODE 39, CODE128, EAN128, GS1 DataBar (including 2D composite), DataMatrix, QR, PDF417 | EAN8, EAN13, UPC-A, CODE128, EAN128, 2/5i, Codabar, CODE39 | Multiple linear and 2D bar codes including DataMatrix, QR, GS1, PPN, HIBC |

| Single printhead print height | 12.7 mm (0.5 in) | ||

| Leader/follower capability | Four printhead options are available with different dimensions to meet line integration requirements | Connect up to 6 printheads, which can print simultaneously, for maximum flexibility | |

| Inks | 8 inks | ||

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes![]() : (866) 871-3226

: (866) 871-3226![]() : inboxusa@videojet.com

: inboxusa@videojet.com

Service & Tech Support![]() : (800) 843-3610 Opt #2

: (800) 843-3610 Opt #2

Customer Service (United States)![]() : (800) 843-3610 Opt #1

: (800) 843-3610 Opt #1![]() : vti.domesticcs@videojet.com

: vti.domesticcs@videojet.com

Customer Service (Canada)![]() : (877) 225-2241 Opt #1

: (877) 225-2241 Opt #1![]() : vti.canadacs@videojet.com

: vti.canadacs@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search