Print best before dates, promotional and other codes on bottles, PET, cans, lids, and other packaging types

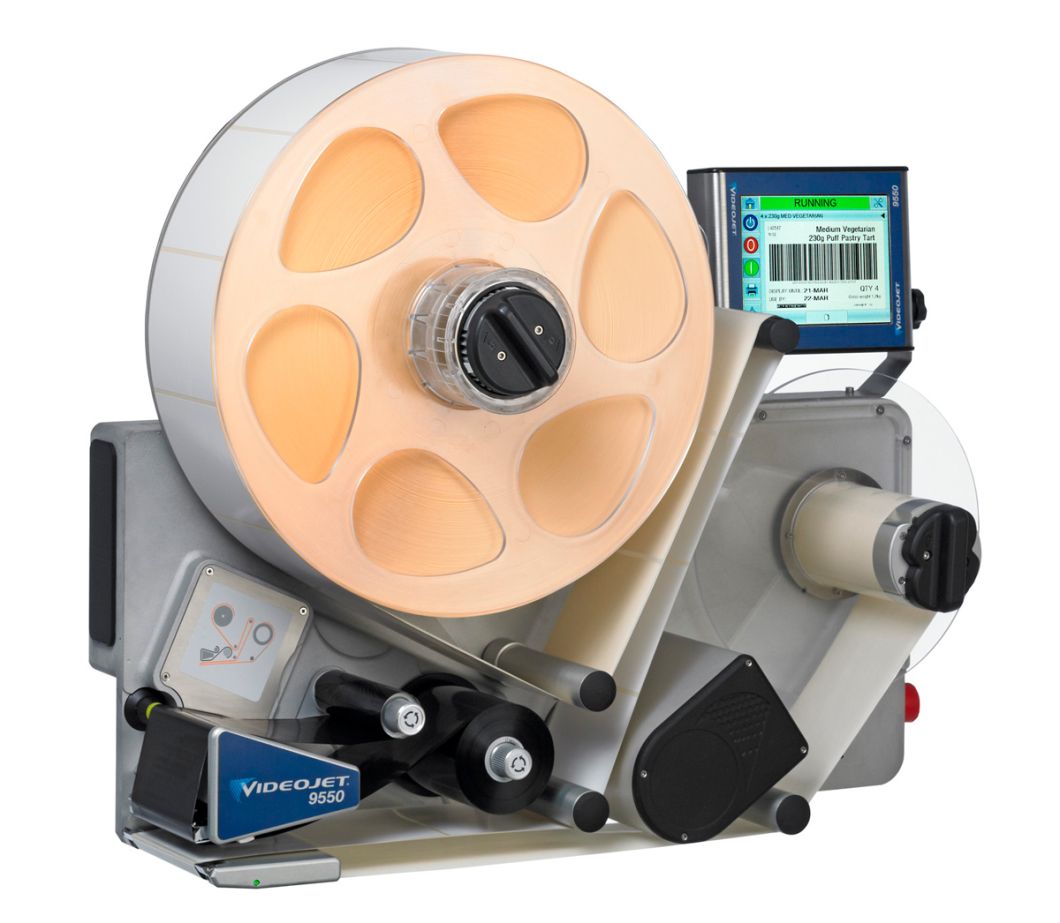

From high line speeds to condensation, beverage producers operate within one of the most demanding production environments. With expensive filling and packaging equipment, producers have no tolerance for unplanned coder downtime. Videojet has a range of high uptime solutions to meet these challenges whether you need to print a simple best before date or more complex promotional and gaming codes.

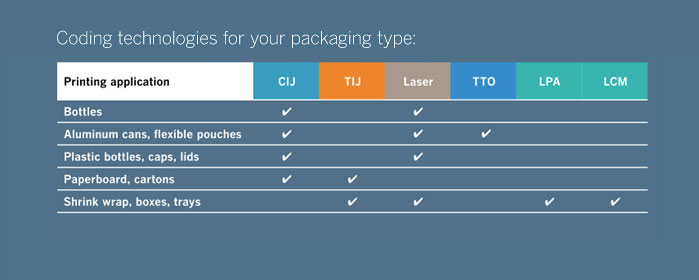

Offering over four decades of experience in the beverage industry, Videojet has a variety of continuous inkjet and laser printers suitable for beverage coding and printing applications with the versatility to code on almost anything.