Part marking provides machine-readable identification for the automotive and aerospace industries

The practice of Direct Part Marking (DPM) is used across many industries to identify an array of end use items. This process, also referred to as machine-readable identification, is prevalent in the automotive and aerospace industries for marking alphanumeric and 2D DataMatrix codes on individual parts and assemblies.

Direct Part Marking, the new standard in parts coding DPM standards have been adopted by a number of associations within the automotive and aerospace industries. Marking parts with machine-readable codes allows for a part to be tracked throughout the manufacturing process and the supply chain.

Manufacturers can use DPM to track parts throughout the manufacturing process and supply chain. It is ideal for locating parts for service or recall and can assist in liability and warranty resolution.

Marking methods

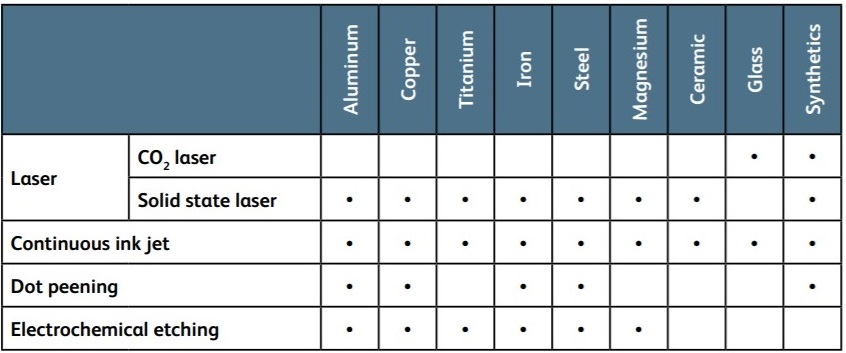

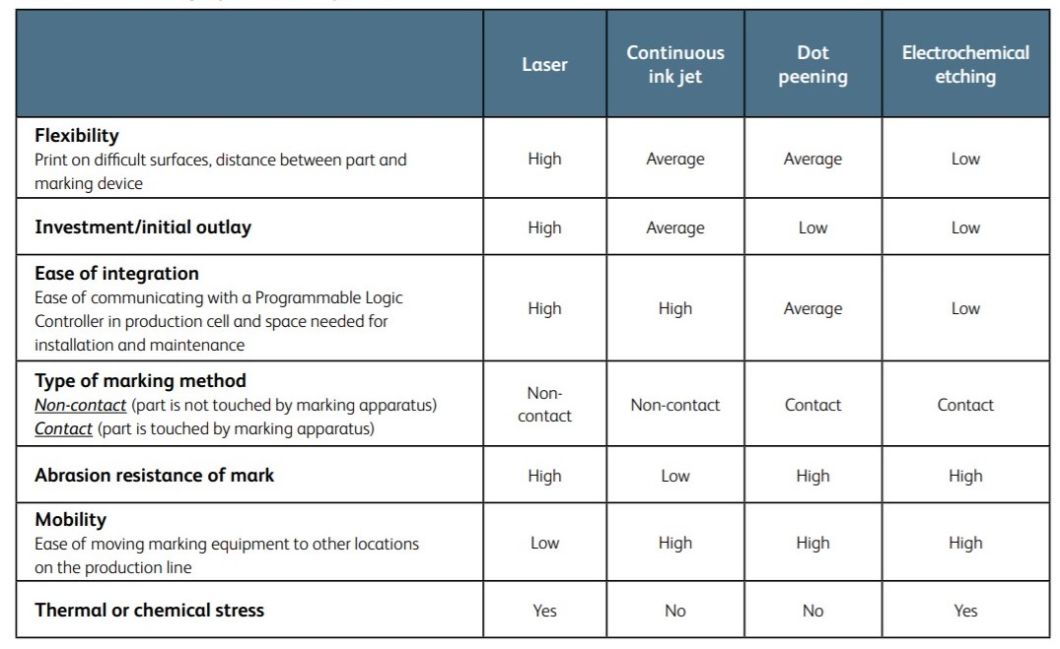

Aside from selecting code formatting and content, it is also important to consider the best method for marking the part. The benefits of DPM are typically greater than that of other options, such as label application. However, the physical characteristics and make-up of the part can also result in marking issues for manufacturers. For the automotive and aerospace industries, the most common coding methods are laser marking, continuous ink jet printing, dot peening and electrochemical etching. When comparing these marking technologies, it is important to focus on the material to be marked, the flexibility of the process, cost factors, speed, throughput and opportunity for automation of the marking process. DPM can be used on a wide variety of materials, but each substrate has unique aspects such as roughness of the substrate, ability to withstand thermal stress, and fragility of the material being marked.

Printing technology and substrate suitability

Common marking options comparison

The bottom line:

Direct part marking is essential to full cycle traceability throughout the manufacturing process and supply chain. A global leader in coding technology, Videojet understands lean manufacturing and the complex demands of direct part marking. Each production environment and product substrate is unique and requires special consideration with the selection of a coding technology. With the move in the industry to 2D coding, manufacturers are transitioning to laser or CIJ printing. Unlike some coding providers in the Automotive and Aerospace industries, Videojet offers a wide range of technologies, including laser and CIJ, helping to make selection of the right solution easier than ever. In fact, many top OEMs and part suppliers already trust our coding specialists and service engineers to help them identify, integrate and maintain the right coding solutions for their production lines and cells. This expertise, combined with outstanding products can help you sustain your nearly non-stop production, even in challenging environments. Trust the expertise of a global leader in product coding. Trust Videojet.