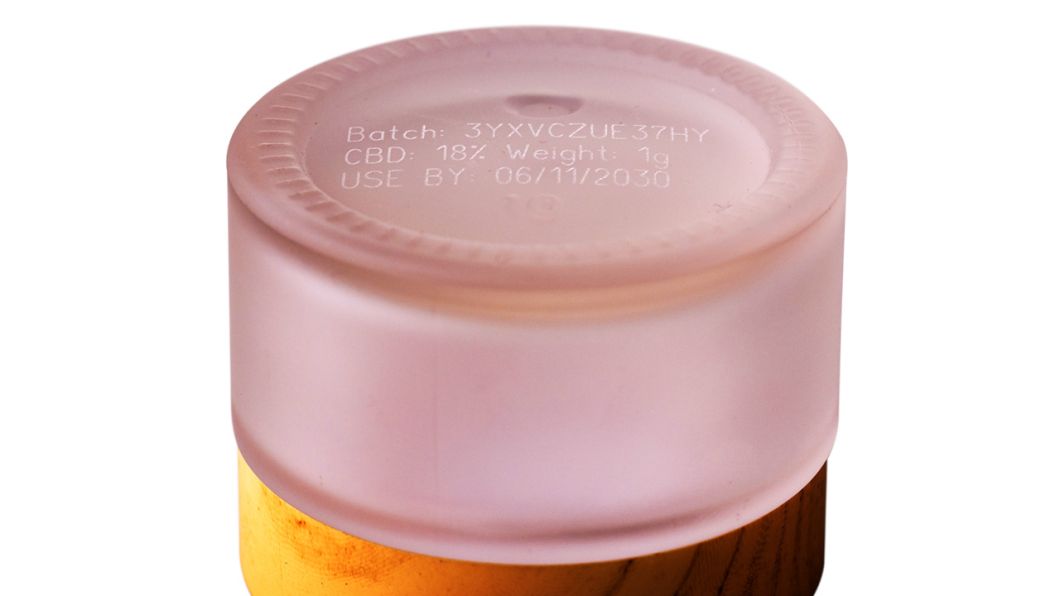

Laser marking produces permanent high-resolution codes on nearly any color or type of glass. The permanent marks protect codes from being tampered with by unauthorized channels. Moreover, the high-quality marks enable clear coding and help instill brand confidence with customers.

Laser benefits

Relative to ink-based printing systems, laser marking offers two advantages concerning cleanliness and code permanence. Laser marking does not degrade the overall cleanliness of the production environment provided a fume extractor is used to address any fumes and/or dust from the ablation process. This helps to provide a cleaner production environment and deliver permanent codes on your products using a laser coding solution. With regards to code permanence, the laser physically alters the substrate and provides a level of code protection for applications where the code may be subject to abrasion.

Technologies for laser marking on glass

CO2 laser marking uses a carbon dioxide laser to create high-contrast marks on glass. This method is ideal for marking glass bottles and other flat glass surfaces, on both clear and colored glass. The advantage of CO2 laser marking is that it produces clear, precise marks with minimal heat transfer, reducing the risk of damage to the glass.

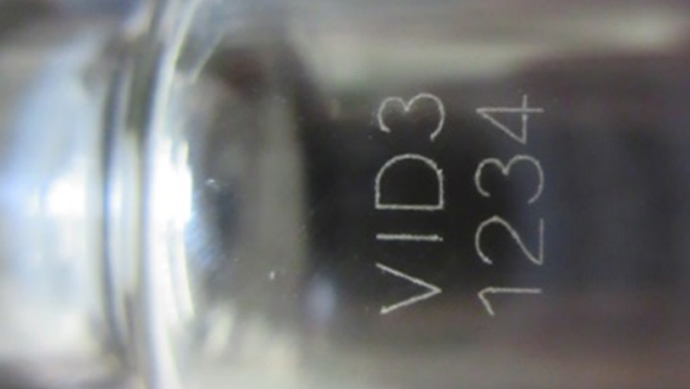

Fiber laser marking utilizes a fiber laser to create marks on glass surfaces. Fiber lasers are known for their high beam quality and can produce fine, intricate marks with excellent precision. This method is ideal for marking glassware, electronics, and other small glass objects.

When choosing the right method for laser marking on glass, there are several considerations to keep in mind. First, the size and shape of the glass object should be considered. Some techniques may be better suited for flat surfaces, while others are more suitable for curved or irregular shapes. Additionally, the desired mark quality, such as clarity, contrast, and permanence, should be considered. Finally, the production volume and speed requirements should also be evaluated to ensure efficiency and cost-effectiveness.

Videojet 3640 CO2 laser and Videojet 7340 fiber laser models provide high-power laser technology specifically optimized for glass marking, ensuring excellent mark quality and permanence. Fast-marking speed and versatile marking area make them an ideal choice for glass manufacturers looking to enhance their marking processes.

At Videojet, we offer cutting-edge laser marking solutions specifically designed for glass applications. Our advanced laser marking systems provide exceptional speed, precision, and versatility, ensuring superior results on glass surfaces. With our expertise and industry-leading technology, we can help you achieve high-quality and durable markings on glass that meet your specific requirements.

For a custom solution, contact a Videojet specialist at (833) 270-0843.

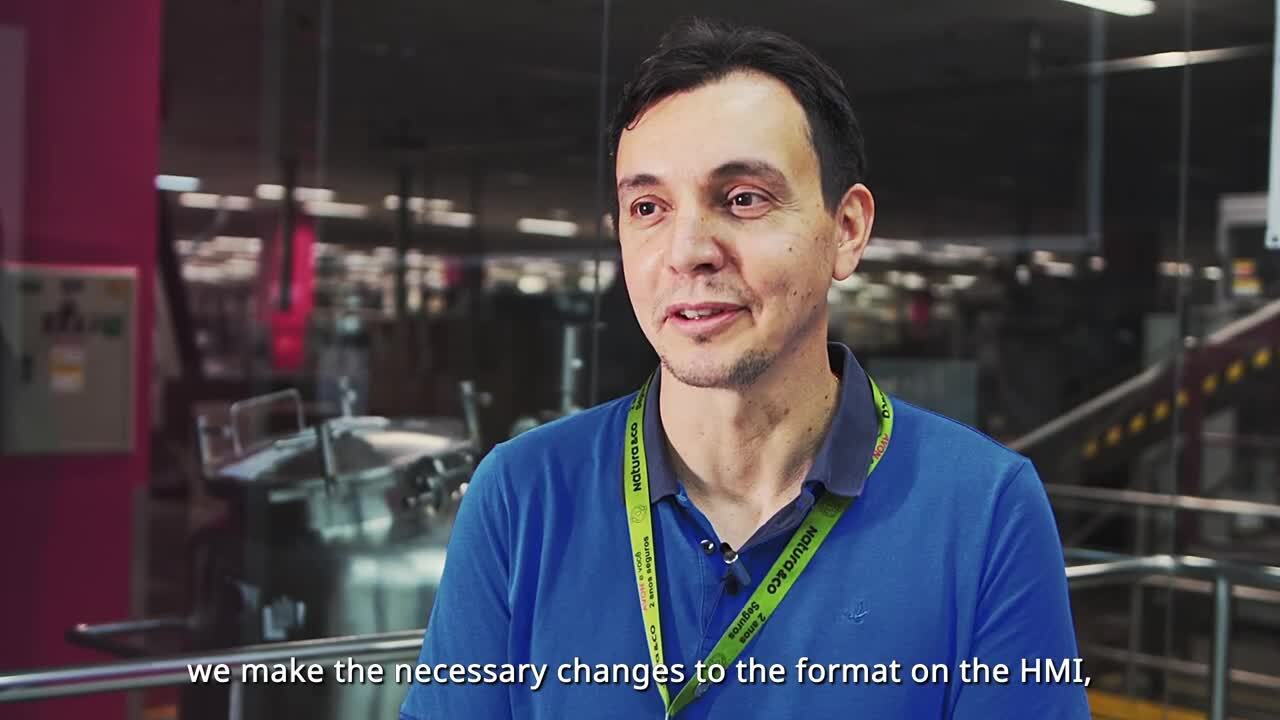

Case study

Videojet helps improve operational efficiency through innovative coding solution at World’s leading drinks business